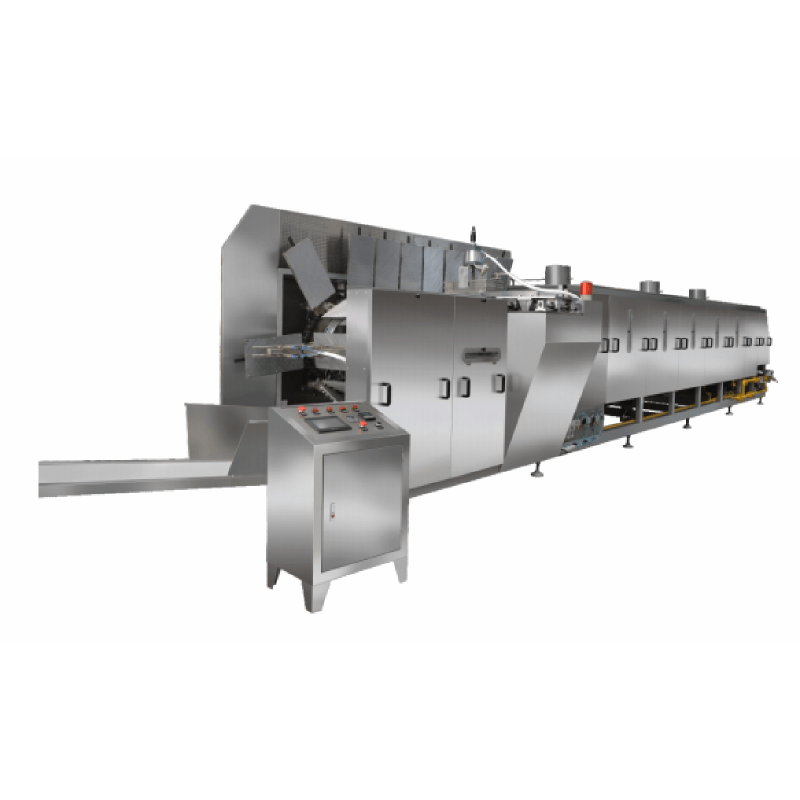

bakery deck oven

A bakery deck oven represents the pinnacle of professional baking equipment, combining traditional baking methods with modern technology. This versatile piece of equipment features multiple independently controlled decks, each offering precise temperature regulation and optimal heat distribution. The oven's construction typically includes heavy-duty materials like stainless steel and thick stone or ceramic decks, which provide excellent heat retention and even baking results. Each deck operates independently, allowing bakers to simultaneously prepare different products at varying temperatures, maximizing productivity and efficiency. The steam injection system, a crucial feature, creates the perfect environment for achieving crusty breads and perfectly baked pastries. Modern deck ovens often incorporate digital controls for accurate temperature management and timing, while maintaining the traditional benefits of stone-deck baking. These ovens are designed to handle a wide range of baked goods, from artisanal breads and pizzas to delicate pastries and cookies, making them indispensable in both small artisanal bakeries and large-scale operations.