blast freezer for ice cream

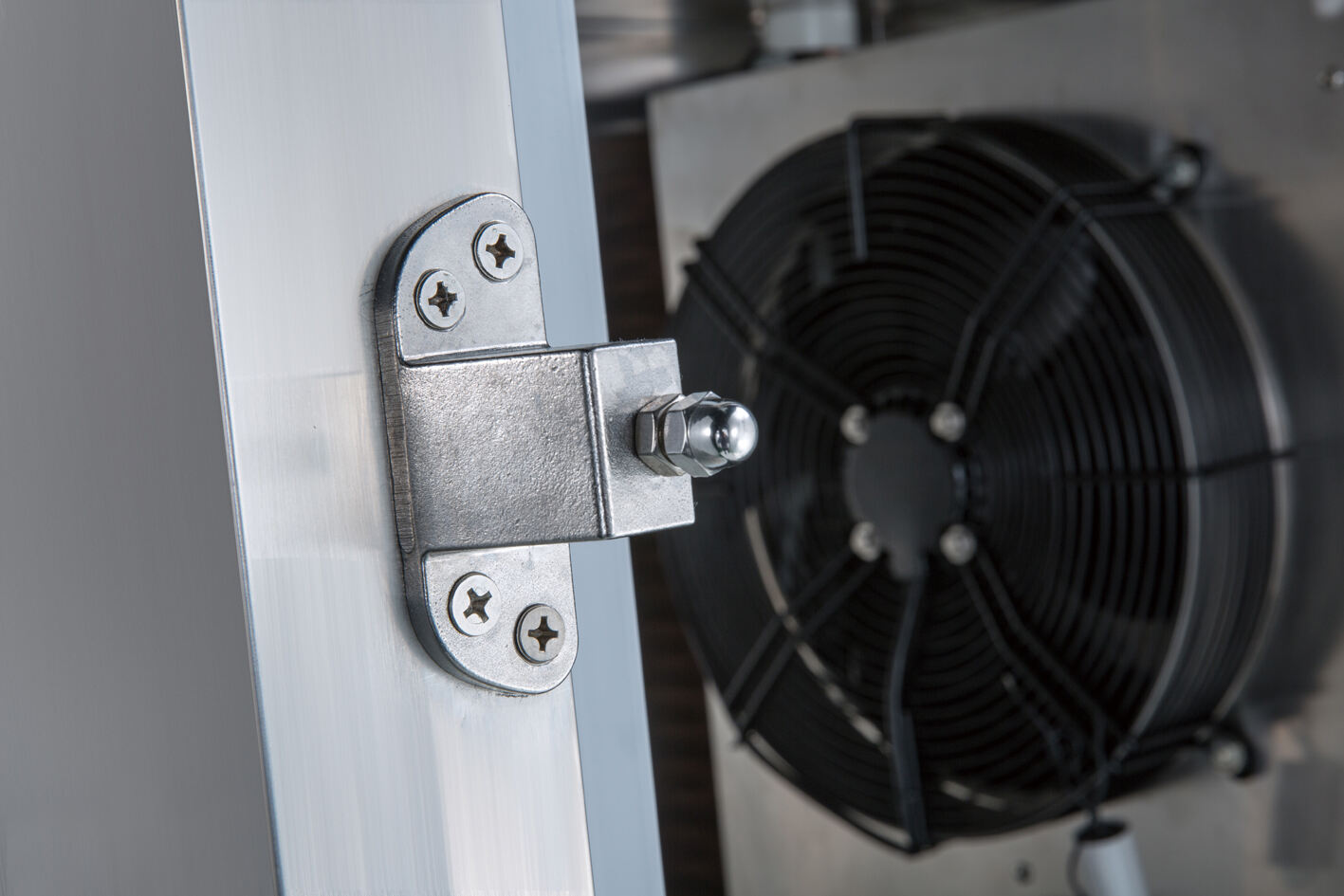

A blast freezer for ice cream is a specialized piece of equipment designed to rapidly freeze ice cream products to maintain optimal texture and quality. Operating at temperatures between -30°F and -40°F (-34°C to -40°C), these freezers utilize powerful compressors and high-velocity fans to create intense cold air circulation. This rapid freezing process prevents the formation of large ice crystals, ensuring a smooth, creamy texture in the final product. The technology employs a combination of cold air distribution and precise temperature control systems, allowing for consistent freezing across multiple batches. Modern blast freezers come equipped with digital control panels, programmable cycles, and advanced monitoring systems that enable operators to customize freezing parameters based on specific recipes and production requirements. These units are available in various sizes, from compact models suitable for artisanal ice cream makers to industrial-scale systems for large-scale production facilities. The rapid freezing capability significantly reduces processing time, allowing for increased production efficiency while maintaining product quality. Many models feature removable shelving systems, making cleaning and maintenance straightforward, while stainless steel construction ensures durability and food safety compliance.