blast freezer manufacturer

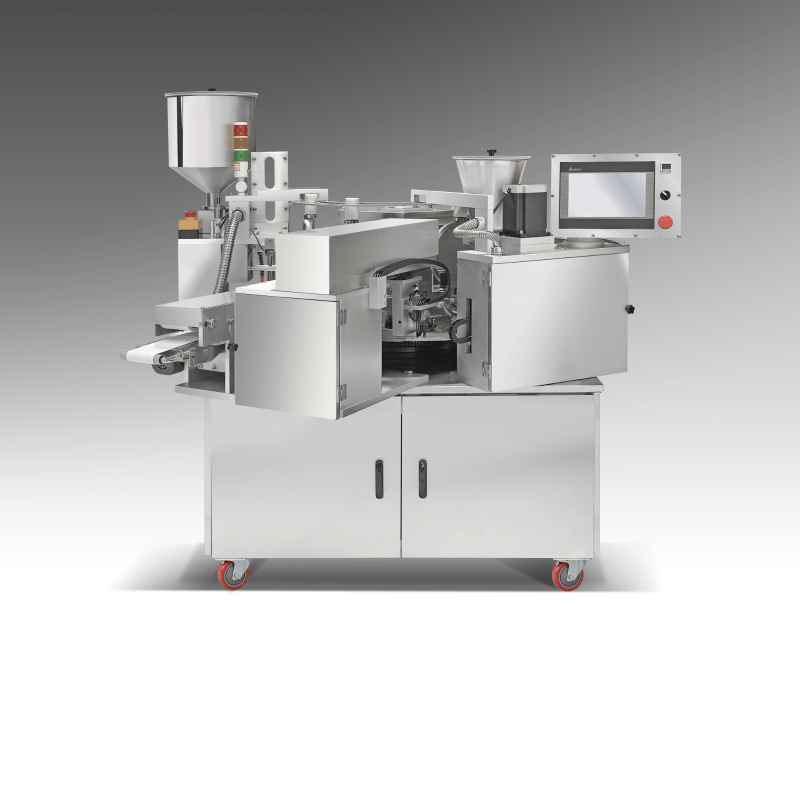

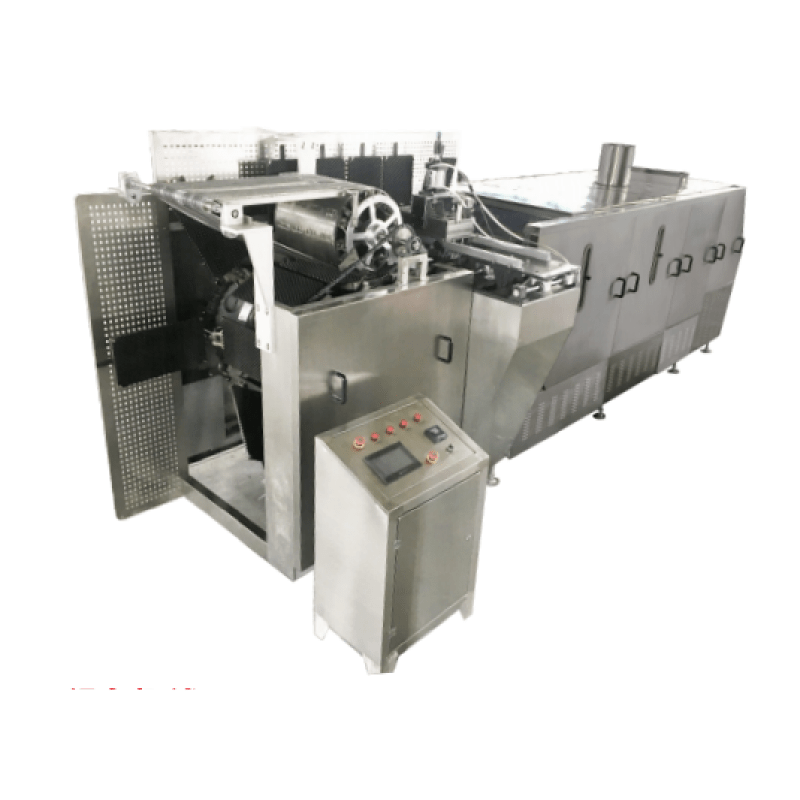

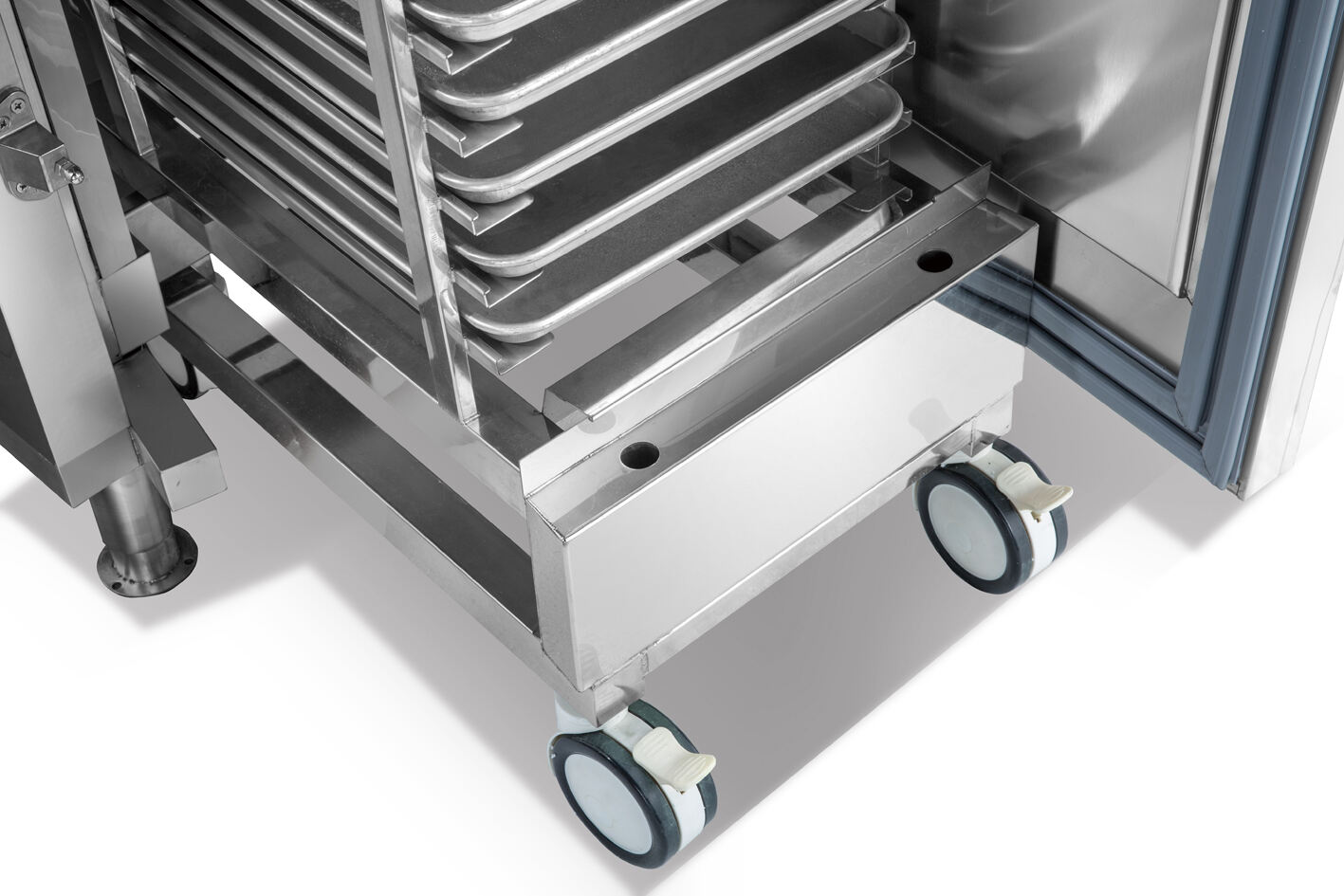

A blast freezer manufacturer specializes in designing and producing advanced cooling systems that rapidly reduce product temperatures to preserve quality and extend shelf life. These sophisticated systems utilize cutting-edge technology to achieve temperatures as low as -40°F (-40°C) within hours, significantly faster than conventional freezing methods. The manufacturer develops customized solutions for various industries, including food processing, pharmaceuticals, and biotechnology. Their systems incorporate precision temperature control, efficient air circulation systems, and robust construction to ensure consistent performance. The manufacturing process involves rigorous quality control measures, from component selection to final assembly, ensuring each unit meets international safety and efficiency standards. Modern blast freezers feature digital control interfaces, remote monitoring capabilities, and energy-efficient operations. The manufacturer provides comprehensive support, including installation, maintenance, and technical consultation. Their expertise extends to developing specialized solutions for specific applications, such as IQF (Individual Quick Freezing) systems for food processing and ultra-low temperature units for pharmaceutical storage. The facilities utilize advanced manufacturing techniques and automated assembly lines to maintain consistent quality while meeting growing market demands.