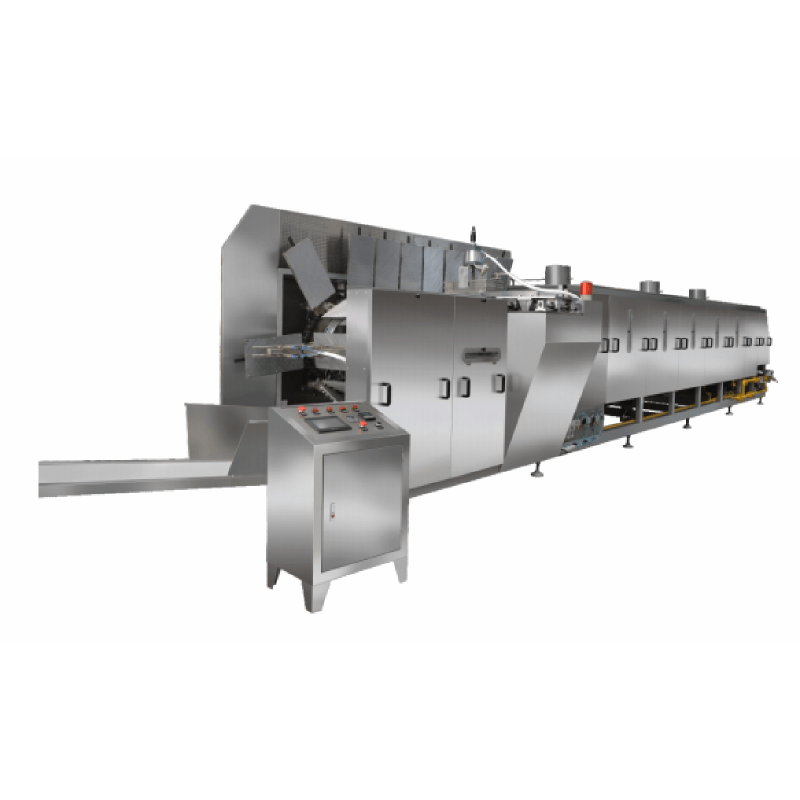

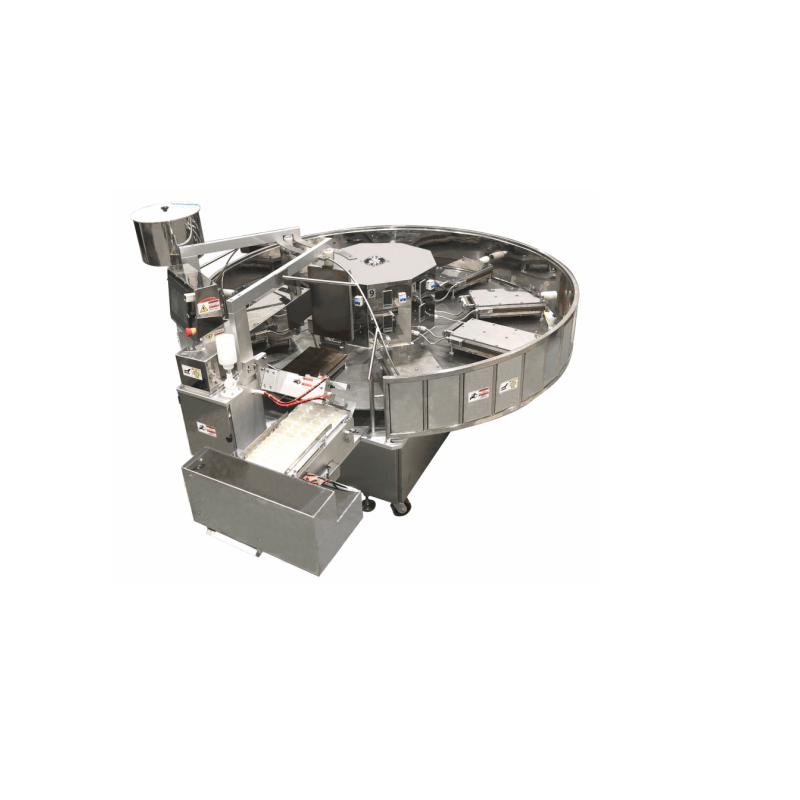

blast freezer supplier

A blast freezer supplier provides essential equipment that revolutionizes the food preservation industry through advanced rapid freezing technology. These specialized units are designed to quickly reduce product temperatures to below freezing, typically reaching -30°F to -40°F in a matter of hours. The rapid freezing process helps maintain food quality by preventing the formation of large ice crystals that can damage cellular structures. Modern blast freezers feature sophisticated digital control systems, allowing precise temperature management and monitoring capabilities. They come equipped with powerful compressors and enhanced airflow systems that ensure uniform freezing throughout the chamber. These suppliers offer various models ranging from compact units suitable for small businesses to industrial-scale systems for large manufacturing facilities. The equipment includes features such as touchscreen interfaces, programmable cycles, and remote monitoring capabilities. Many suppliers also provide customization options to meet specific industry requirements, whether for seafood, bakery products, prepared meals, or pharmaceutical applications. They typically offer comprehensive installation services, technical support, and maintenance programs to ensure optimal performance and longevity of the equipment. The suppliers stay current with evolving food safety regulations and energy efficiency standards, incorporating these requirements into their product designs and specifications.