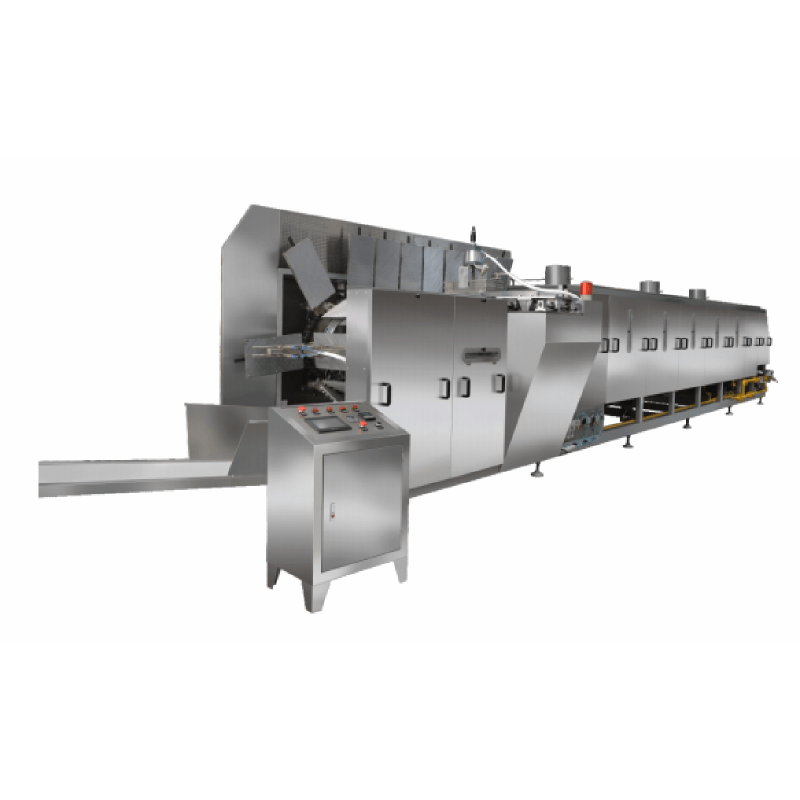

commercial convection oven for bakery

A commercial convection oven for bakery operations represents a cornerstone of modern baking technology, designed to deliver consistent, high-quality results across a wide range of baked goods. This sophisticated piece of equipment utilizes advanced forced-air circulation systems to ensure even heat distribution throughout the baking chamber, eliminating hot spots and ensuring uniform browning. The oven typically features multiple rack positions, digital temperature controls, and programmable settings that allow bakers to store and recall specific recipes. With temperature ranges typically spanning from 150°F to 500°F, these ovens can accommodate everything from delicate pastries to hearty breads. Most models come equipped with humidity control systems that help achieve the perfect crust development and maintain ideal moisture levels during baking. The robust construction includes heavy-duty stainless steel exteriors and reinforced door hinges designed to withstand constant use in busy commercial environments. Advanced models often incorporate energy-efficient features such as double-pane glass doors and superior insulation, helping to reduce operational costs while maintaining optimal baking conditions. These ovens can handle multiple baking sheets simultaneously, significantly increasing production capacity compared to traditional ovens.