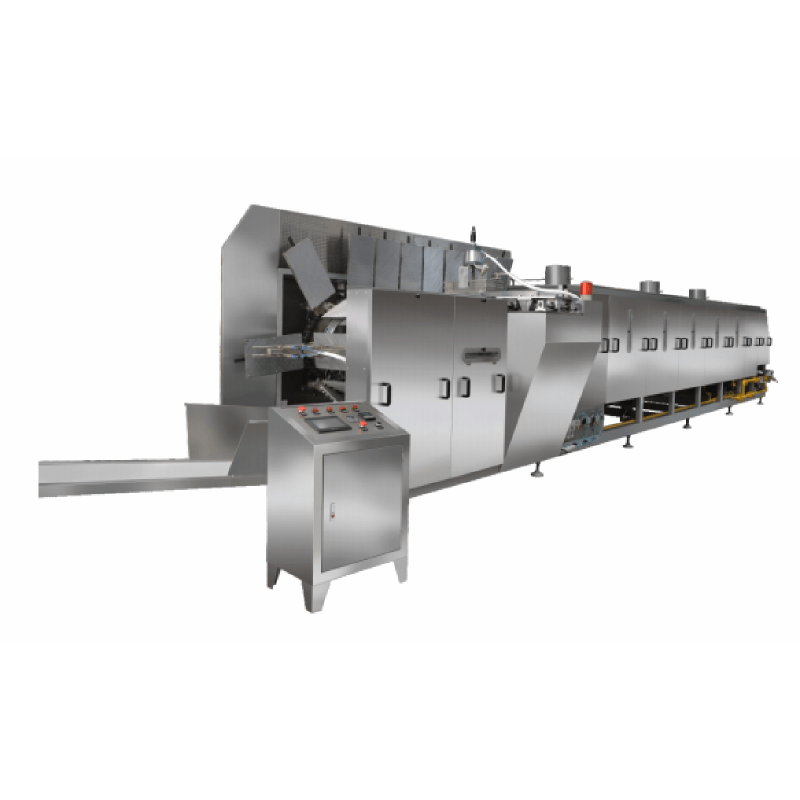

used deck oven with steam

A used deck oven with steam represents a versatile and cost-effective solution for professional baking operations. This commercial-grade equipment combines traditional deck baking technology with advanced steam injection systems, offering superior baking control and consistency. The multi-deck configuration allows for simultaneous baking of different products at varying temperatures, maximizing productivity and operational efficiency. Each deck features independent temperature controls, steam injection capabilities, and precise timing mechanisms, ensuring optimal baking conditions for a wide range of products. The steam system delivers controlled moisture during the baking process, essential for achieving the perfect crust development, surface shine, and product expansion. These ovens typically include digital control panels for accurate temperature and steam management, heavy-duty insulation for energy efficiency, and durable stainless steel construction for longevity. The steam generation system incorporates professional-grade boilers or injection methods, providing consistent humidity levels throughout the baking chamber. With adjustable ventilation systems and steam evacuation controls, these ovens offer bakers complete control over the baking environment, making them ideal for producing artisan bread, pastries, and other baked goods that require precise moisture control.