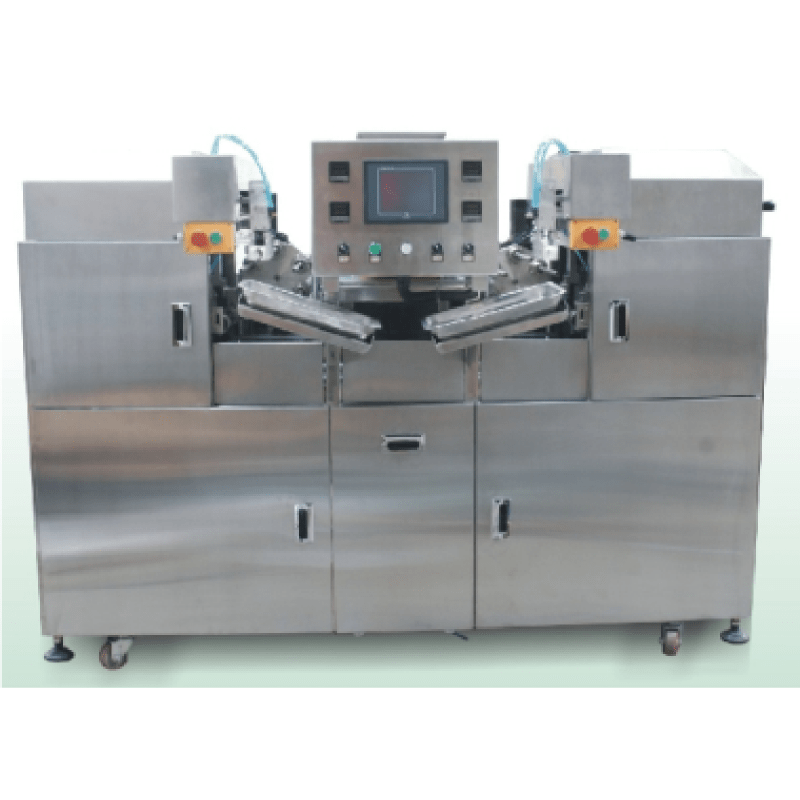

bakery bread mixer

A bakery bread mixer is an essential piece of commercial kitchen equipment designed to efficiently combine and knead ingredients for various bread recipes. These robust machines feature powerful motors ranging from 1 to 3 horsepower, capable of handling both small and large batches of dough. The mixer comes equipped with multiple speed settings and specialized attachments, including dough hooks, flat beaters, and wire whips, allowing for versatile mixing applications. Modern bakery bread mixers incorporate advanced digital controls for precise timing and speed regulation, ensuring consistent results every time. The bowl capacity typically ranges from 20 to 80 quarts, making them suitable for different production scales. These machines are constructed with durable stainless steel components, featuring planetary mixing action that ensures thorough ingredient incorporation. Safety features include bowl guards, emergency stop buttons, and thermal overload protection. The mixers often come with removable bowls for easy cleaning and maintenance, while their heavy-duty construction ensures stability during operation. Many models also include bowl lift systems for ergonomic handling and timer functions for automated operation.