- Página principal

- Sobre Nosotros

-

Productos

- Equipo de Panadería

-

Preparación De Alimentos

- Mezclador De Alimentos

- Batidora De Inmersión

- Mezclador Espiral

- Enfriador De Agua

- Laminadora De Masa

- Divisor De Masa

- Máquina De Amasar Masa

- Laminadora De Pizza

- Modeladora De Masa

- Rebanadora De Pan

- Máquina Para Hacer Pasteles

- Picadora De Carne

- Cortador De Carne

- Sierra de Huesos

- Máquina de Albóndigas

- Máquina de Relleno de Salchicha

- Máquina De Relleno

- Cortador de Sandía y Frutas

- Cortador de Alimentos

- Máquina de Lavar y Pelar

- Máquina de Leche de Soya y Tofu

- Molino Eléctrico de Cereales

- Extrusor de Caña de Azúcar

- Calentador de Agua

- Máquina Selladora de Vasos

- Esterilizador

- Máquina de Embalaje al Vacío

-

Equipo de Cocina

- Grupo de Cocina de Suelo

- Grupo de Cocina de Encimera

- Freidora

- Plancha

- Quemador de Gas

- Máquina de Kebab

- Barbacoa

- Asadores De Pollos

- Calentador De Alimentos

- Carro Para Cocer Arroz

- Bain Marie

- Mostrador Caliente

- Grill De Salchichas

- Tostador De Pan

- Gabinete De Vapor

- Cocina De Inducción

- Teppanyaki

- Marinador

- Papitas Escotilla

- Máquina De Hamburguesas

- Máquina De Algodón De Azúcar

- Máquina De Palomitas

- Asador De Pellets De Pescado

- Hacedor De Waffles

- Fritador De Donuts

- Máquina De Crepes

- Bandeja De Calentamiento Y Luz

- Máquina De Donuts

- Arrocera

- Deslicador De Chocolate

- Olla Eléctrica Para Sopa

-

Equipo De Refrigeración

- Vitrina De Pasteles

- Vitrina De Helados

- Vitrina De Bebidas

- Enfriador De Vino

- Vitrina De Supermercado

- Mini Enfriador

- Gabinete Refrigerado

- Refrigeradores Y Congeladores De Puerta De Vidrio

- Congelador De Choque

- Mesa Refrigerada

- Vitrina De Sushi

- Congelador De Engaño

- Bar De Ensaladas

- Cámara Frigorífica De Acceso

- Equipo Para Bar

- Acero Inoxidable

-

Línea De Producción

- Línea De Procesamiento De Naranjas

- Máquina De Rollitos De Huevo Artesanal GL-12

- Máquina De Rollitos De Huevo Artesanal GL-06

- Máquina De Formado De Rollos De Algas

- Máquina Automática Para Rolls De Fénix

- Máquina De Rollos De Huevo Automática

- Máquina De Tortilla Automática Guijiabei

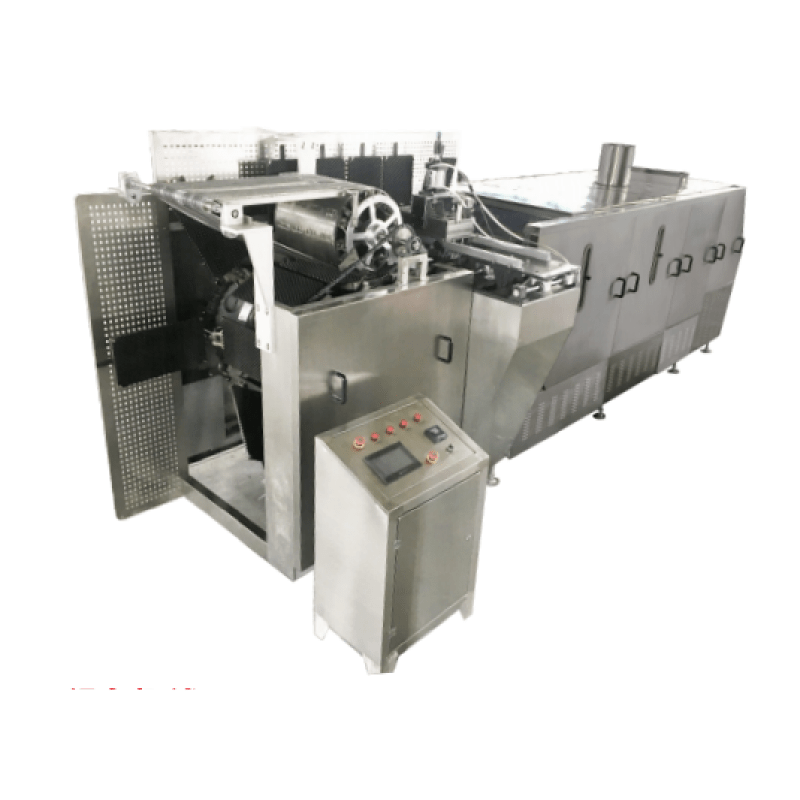

- Línea De Producción De Rollos De Huevo Automática A Gas

- Línea De Producción De Gofres Suaves En Ocho Modos

- Línea De Producción Automática De Crepes Europeos

- Línea De Producción De ShaQima

- Línea De Producción Automática De Pequeños Panes Al Vapor

- Línea De Producción Automática De Rollos De Huevo (9 Moldes)

- Serie De Barras Personalizadas Para Bares De Bar

- Serie Personalizada de Diseño de Hornos de Hotel

- Lavandería

- Utensilio

- Lavavajillas

- servicio

- Noticias

- Contacta con nosotros