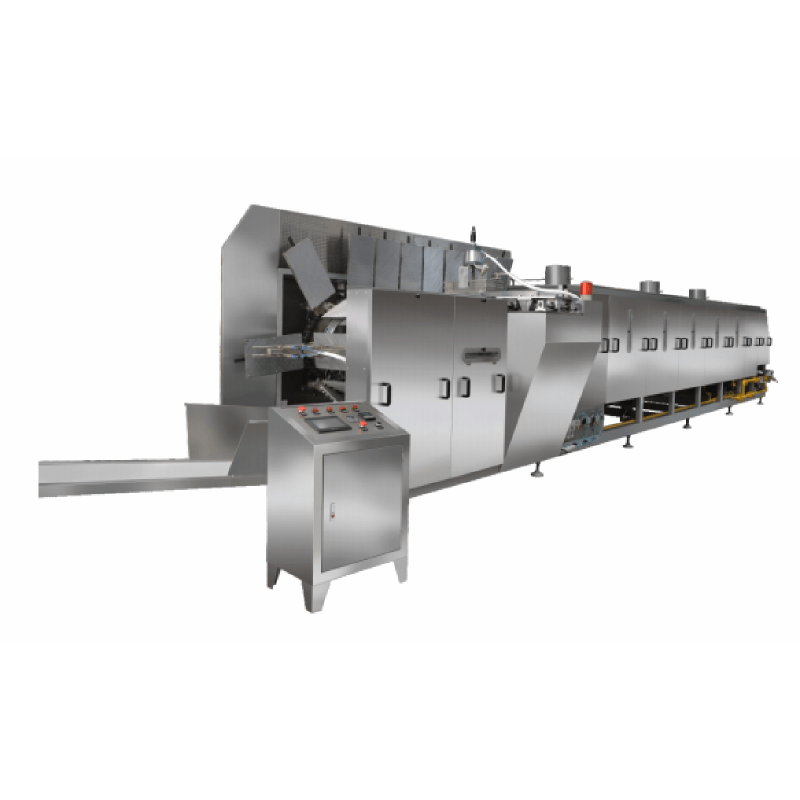

forno de convecção elétrico para padaria

O forno de convecção elétrico para padaria representa um ponto alto da tecnologia moderna de padaria, combinando aquecimento preciso com sistemas avançados de circulação de ar para oferecer resultados excepcionais de cocção. Esta sofisticada peça de equipamento utiliza potentes ventiladores para circular o ar quente uniformemente por toda a câmara de cozimento, garantindo uma distribuição homogênea de calor e resultados consistentes em várias prateleiras. O forno possui controles digitais que permitem uma gestão precisa da temperatura, geralmente variando de 50°C a 300°C, tornando-o adequado para uma ampla gama de aplicações de cocção. Múltiplos modos de cocção atendem a diversas necessidades de assadura, desde fermentação suave até cocção intensiva. O sistema de convecção reduz os tempos de cocção em até 25% em comparação com fornos tradicionais, enquanto mantém uma qualidade superior. Esses fornos vêm equipados com sistemas de injeção de vapor que criam o ambiente perfeito para pães crocantes e massas folhadas. A maioria dos modelos apresenta portas de vidro duplo para melhor retenção de calor e eficiência energética, além de iluminação interna para monitoramento fácil. A construção em aço inoxidável garante durabilidade e facilidade de limpeza, enquanto as prateleiras ajustáveis proporcionam flexibilidade para diferentes tamanhos de lote. Modelos avançados incluem configurações programáveis para armazenar receitas frequentemente usadas e sistemas de controle de vapor automatizados para liberação de umidade perfeitamente cronometrada durante o processo de cocção.