- Home

- About Us

-

Products

- Baking Equipment

-

Food Preparation

- Food Mixer

- Immersion Blender

- Spiral Mixer

- Water Cooler

- Dough Sheeter

- Dough Divider

- Pressing Dough Machine

- Pizza Sheeter

- Dough Muolder

- Bread Slicer

- Cake Making Machine

- Meat Grinder

- Meat Cutter

- Bone Saw

- Meat Ball Machine

- Saugsage Filling Machine

- Filling Machine

- Melon And Fruit Cutter

- Food Cutter

- Washing And Peeling Machine

- Soybean Milk And Bean Curd Mach

- Electric Cereal Mill

- Sugarcane Presser

- Water Boiler

- Cup Sealing Machine

- Sterilizer

- Vacuum Packing Machine

-

Cooking Equipment

- Floor Type Cooking Group

- Counter Top Cooking Group

- Fryer

- Griddle

- Gas Burner

- Kebab Machine

- Barbucue

- Rotisseries

- Food Warmer

- Rice Steaming Cart

- Bain Marie

- Warming Display

- Hot Dog Grill

- Bread Toster

- Steam Cabinet

- Induction Cooker

- Teppanyaki

- Marinator

- Chips Scuttle

- Hamburger Machine

- Cotton Candy Machine

- Popcorn Machine

- Fish Pellet Grill

- Waffle Maker

- Dount Fryer

- Crepe Machine

- Warming Tray And Light

- Dount Machine

- Rice Cooker

- Chocolate Melter

- Electric Soup Pot

- Refrigeration Equipment

- Bar Equipment

- Stainless Steel

-

Production Line

- Orange Processing Line

- GL-12 Handcrafted Egg Roll Machine

- GL-06 Handcrafted Egg Roll Machine

- Seaweed Roll Forming Machine

- Automatic Machine For Phoenix Rolls

- Automatic Egg Roll Machine

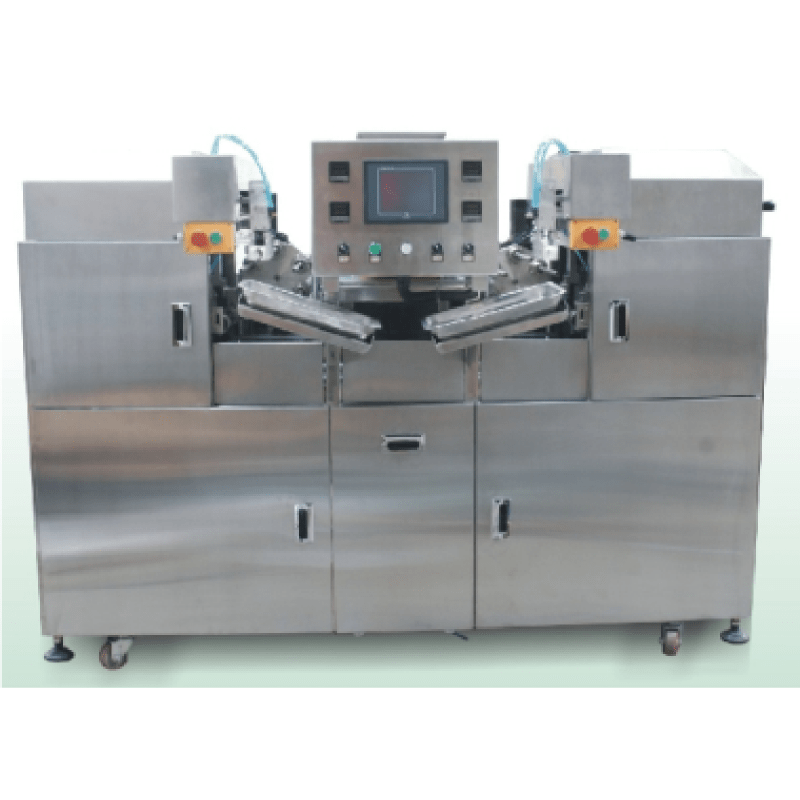

- Automatic Guijiabei Omelet Machine

- Gas Automatic Wafer Egg Roll Production Line

- Eight Mode Soft Waffle Production Line

- European Battercake Automatic Production Line

- ShaQima Production Line

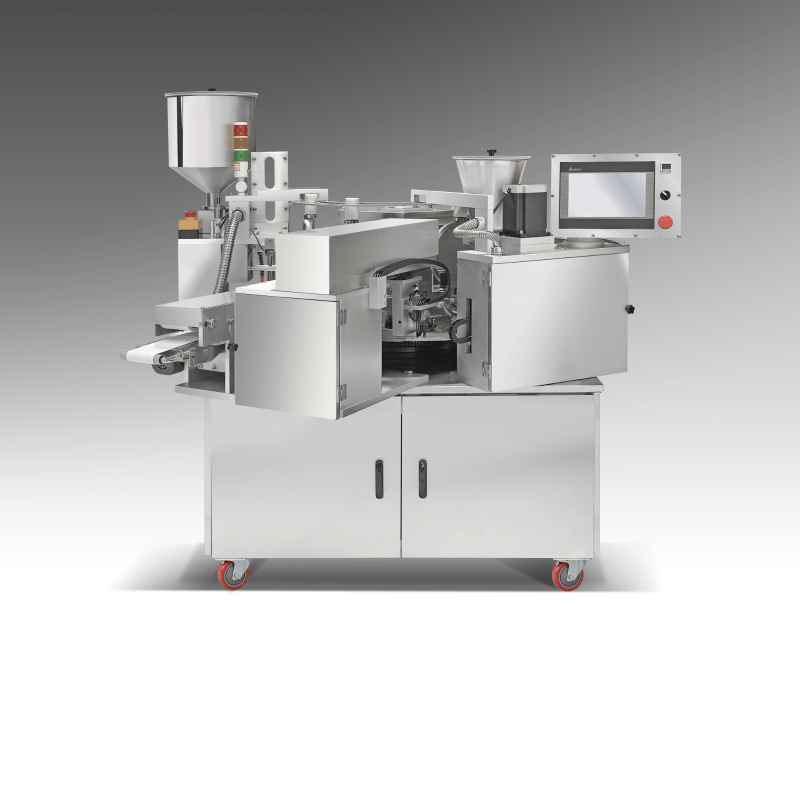

- Automatic Small Steamed Bread Production Line

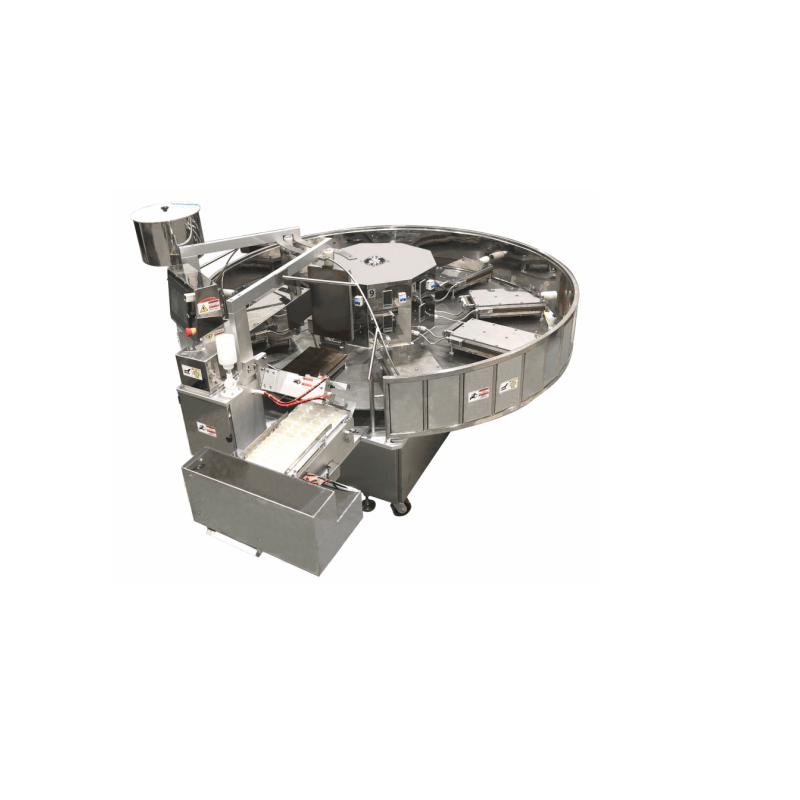

- Automatic (9-mold) Egg Roll Production Line

- Bar Bartender Custom Bar Series

- Hotel Buffet Stove Desigh Custom Series

- Laundry

- Utensil

- Dishwasher

- Service

- News

- Contact Us