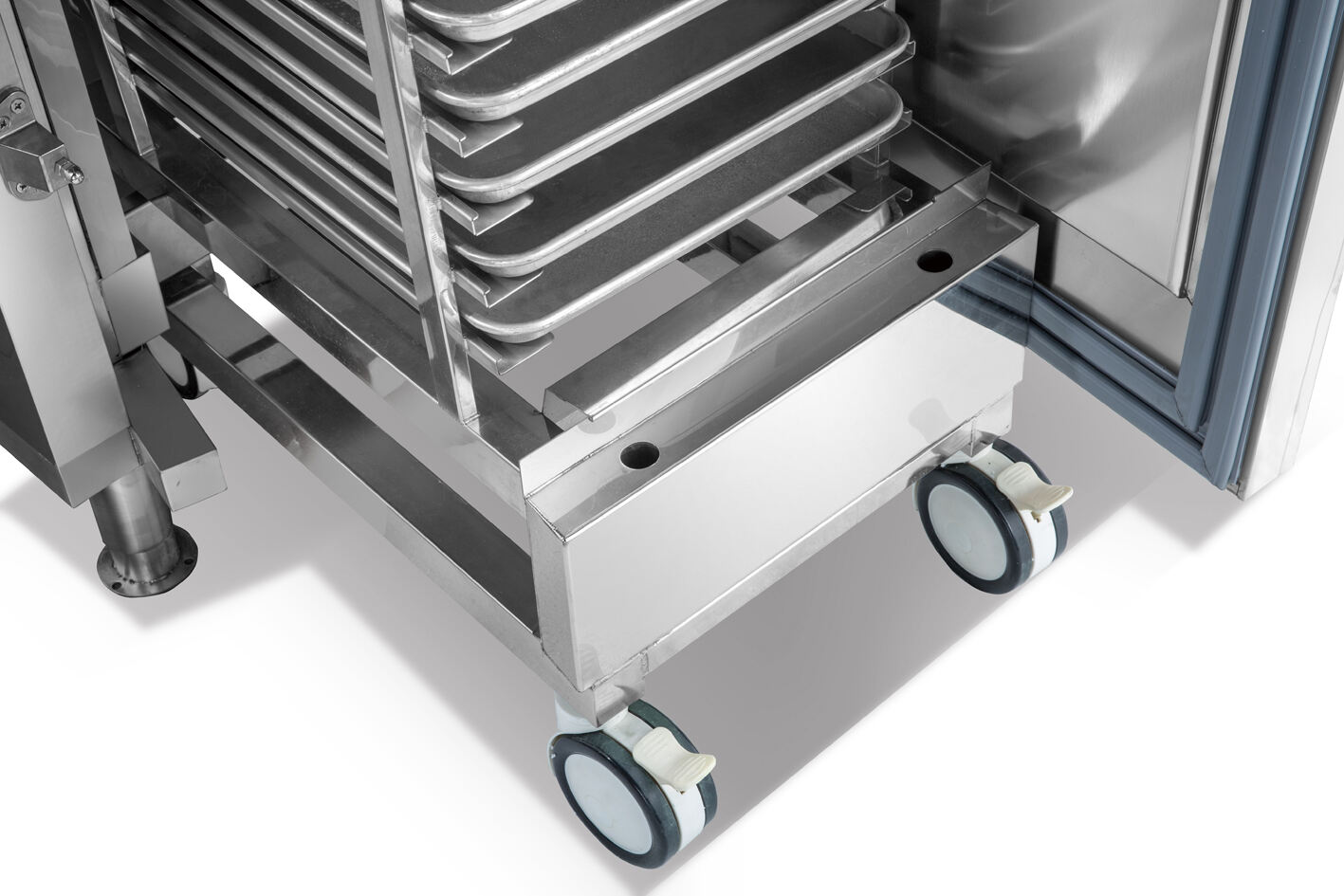

ice cream blast freezer for sale

The ice cream blast freezer for sale represents cutting-edge technology in the frozen dessert industry, offering rapid freezing capabilities essential for producing high-quality ice cream products. This advanced freezing system utilizes powerful compressors and efficient cooling mechanisms to achieve temperatures as low as -40°F (-40°C), ensuring optimal crystallization of ice cream mixtures. The unit features precise temperature control systems, allowing operators to maintain consistent freezing conditions throughout the production process. Its robust stainless steel construction ensures durability and compliance with food safety standards, while the user-friendly digital control panel enables easy operation and monitoring of freezing cycles. The blast freezer accommodates various container sizes and can process multiple batches simultaneously, making it ideal for both small-scale artisanal operations and larger commercial productions. The system incorporates advanced airflow technology that promotes uniform freezing, preventing ice crystal formation and ensuring smooth, creamy textures in the final product. Additionally, the energy-efficient design helps reduce operational costs while maintaining superior freezing performance.