blast freezer cost

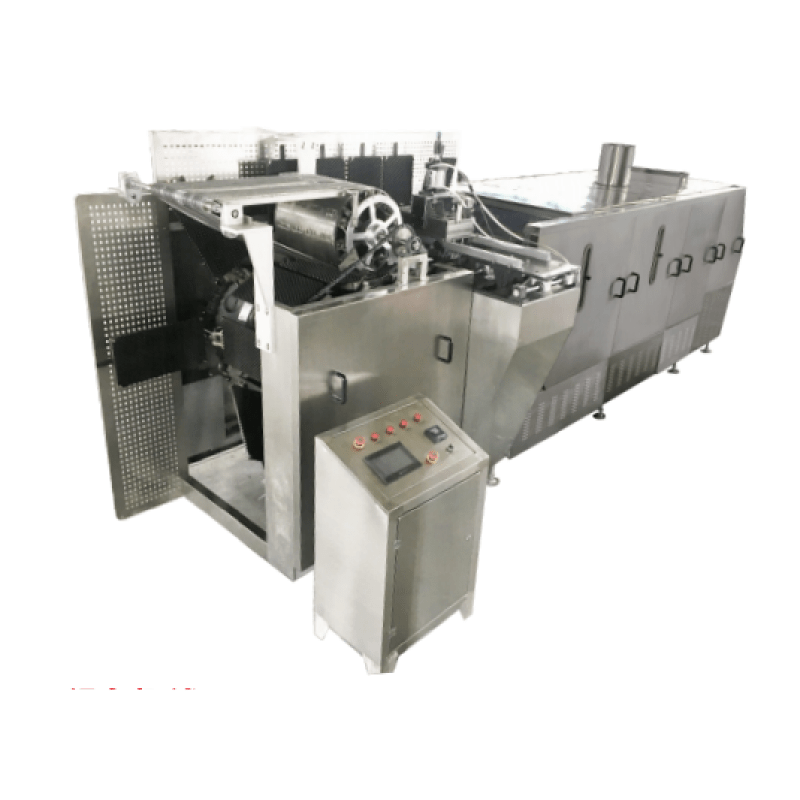

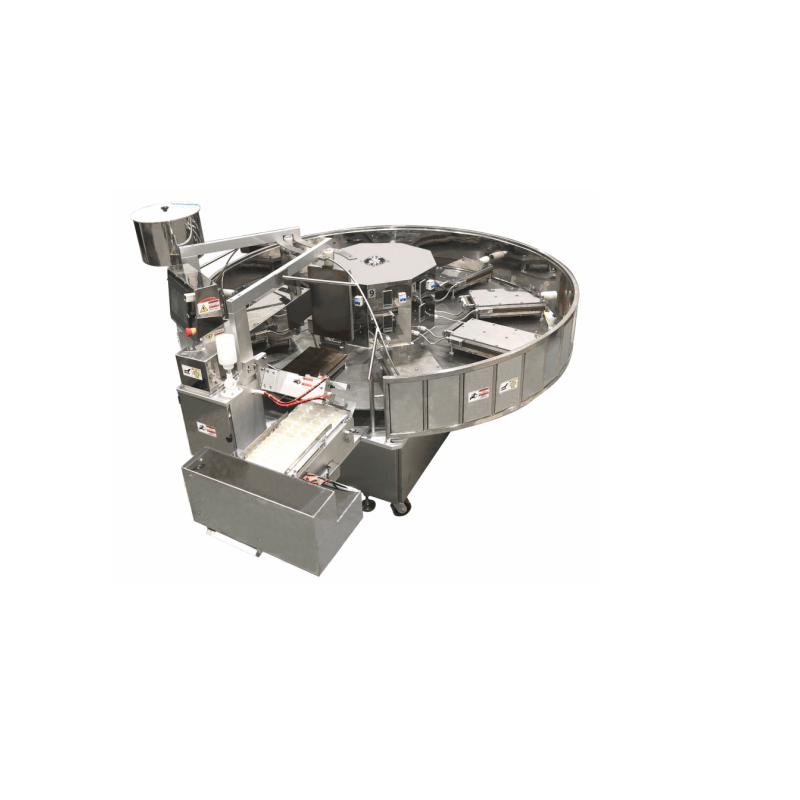

Blast freezer costs encompass various factors that businesses must consider when investing in this essential food preservation technology. These industrial-grade freezing systems, ranging from $15,000 to $50,000, represent a significant but valuable investment for food processing operations. The cost varies depending on size, capacity, and technological features, with smaller units starting at the lower end and industrial-scale systems commanding premium prices. Modern blast freezers incorporate advanced features such as digital temperature controls, energy-efficient components, and smart monitoring systems. The initial investment includes installation costs, which typically add 10-15% to the base price. Operating costs factor in electricity consumption, maintenance requirements, and potential repairs. These freezers operate by circulating extremely cold air at high velocities, rapidly bringing food products to temperatures below -30°F (-34°C). This rapid freezing process preserves food quality, reduces bacterial growth, and extends shelf life significantly. The technology is particularly valuable for restaurants, food manufacturers, and industrial kitchens handling large volumes of perishable goods. When calculating total blast freezer costs, businesses should consider long-term operational expenses, including energy consumption, which can range from $200 to $600 monthly depending on usage patterns and local utility rates.