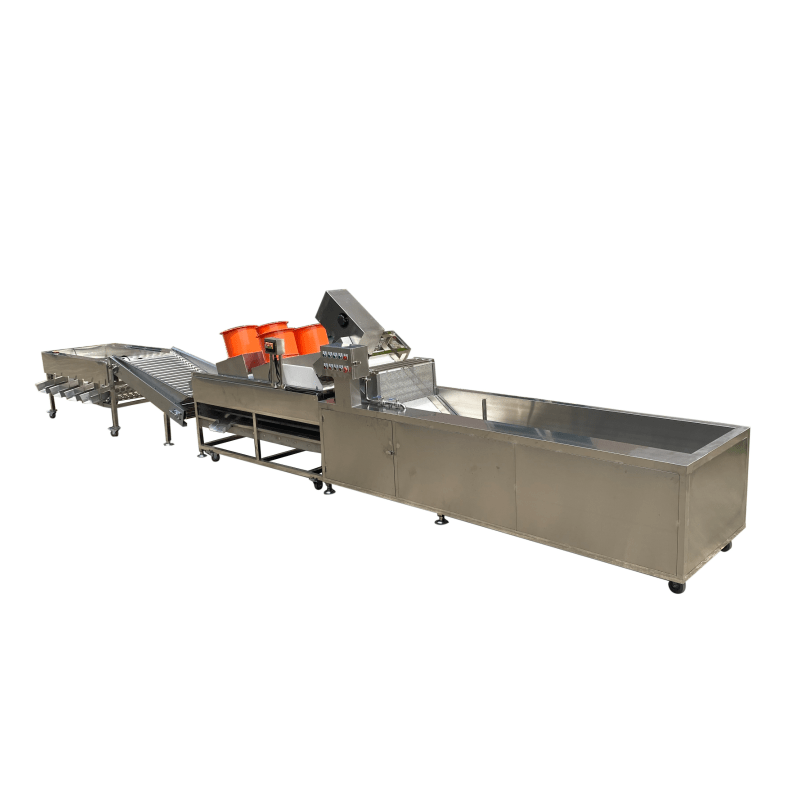

blast freezer for fish

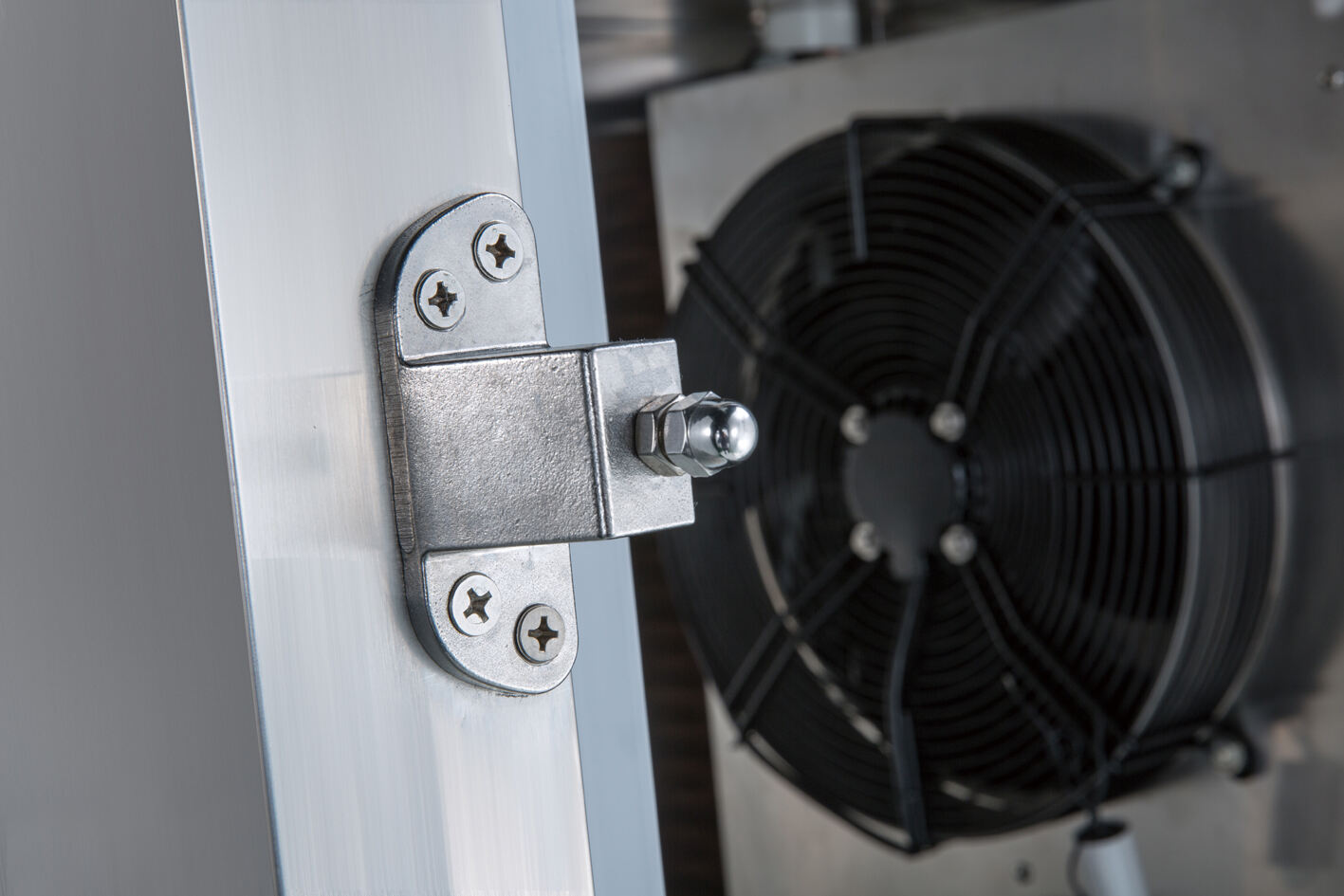

A blast freezer for fish is an advanced refrigeration system designed specifically for rapid freezing of seafood products. This specialized equipment operates by circulating extremely cold air at high velocities around the product, typically at temperatures ranging from -22°F to -31°F (-30°C to -35°C). The system employs powerful fans and advanced refrigeration technology to achieve rapid freezing times, which is crucial for maintaining the quality and texture of fish products. The freezing process occurs in stages, starting with the initial blast that quickly brings the product temperature down, followed by a stabilization period. This equipment features adjustable temperature controls, multiple storage compartments, and efficient air circulation systems that ensure uniform freezing throughout the chamber. The blast freezer's design typically includes stainless steel construction for durability and food safety, insulated walls for maximum efficiency, and easy-to-clean surfaces. Modern units often come equipped with digital controls, monitoring systems, and programmable cycles that can be customized for different types of fish and seafood products. These freezers are available in various sizes and configurations, from compact units suitable for small-scale operations to industrial-scale systems capable of processing thousands of pounds of fish per cycle.