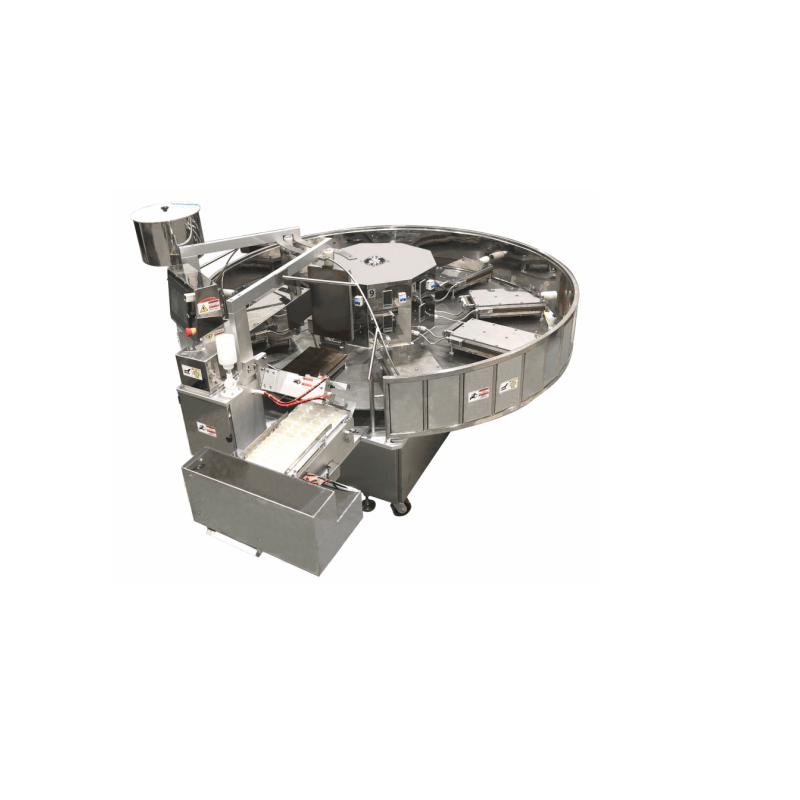

spiral blast freezer

A spiral blast freezer represents a cutting-edge solution in industrial food freezing technology, designed to efficiently freeze large quantities of food products while maintaining their quality and nutritional value. This sophisticated system utilizes a continuous spiral conveyor belt that moves products through multiple tiers within an insulated enclosure, maximizing vertical space usage. The freezing process is achieved through powerful blast freezing technology that circulates extremely cold air at high velocities, typically between -22°F and -40°F, ensuring rapid freezing of products. The spiral design allows for extended freezing time while minimizing floor space requirements, making it ideal for facilities with space constraints. The system's automated operation includes precise temperature control, variable belt speeds, and advanced defrosting mechanisms. Its versatility accommodates various food products, from meat and seafood to baked goods and prepared meals, handling items of different sizes and shapes. The freezer's design incorporates food safety features, including stainless steel construction and easy-clean surfaces, ensuring compliance with strict hygiene standards. Modern spiral blast freezers also feature energy-efficient components and smart monitoring systems that optimize performance while reducing operational costs.