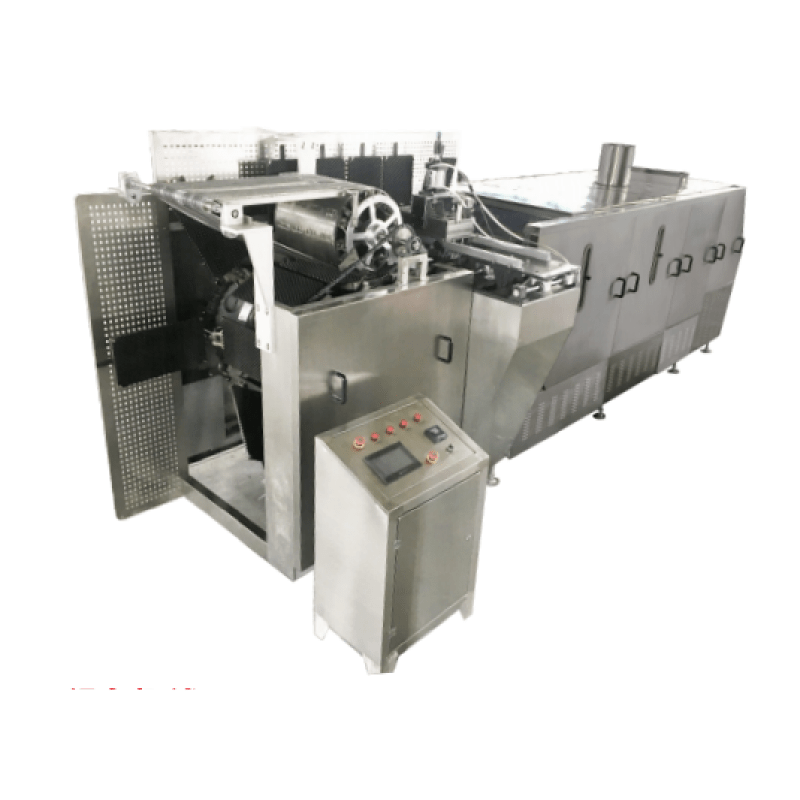

blast freezer industrial

A blast freezer industrial is a sophisticated cooling system designed to rapidly reduce the temperature of products to below freezing point in minimal time. This advanced freezing technology operates by circulating extremely cold air at high velocities across the product, typically achieving temperatures between -30°C and -40°C. The system employs powerful compressors and specialized evaporator coils to create an intense freezing environment that prevents the formation of large ice crystals in food products, thereby maintaining their quality and structural integrity. These industrial-grade freezers are equipped with precise temperature controls, automated loading systems, and energy-efficient components that ensure consistent performance while minimizing operational costs. The rapid freezing process is particularly crucial in food processing facilities, pharmaceutical manufacturing, and other industries where maintaining product quality through quick temperature reduction is essential. Most modern blast freezers incorporate smart monitoring systems that provide real-time temperature data and automated defrost cycles, ensuring optimal performance and reducing maintenance requirements. Their versatile design allows for various configuration options, including tunnel freezers, spiral freezers, and batch freezers, making them adaptable to different production needs and space constraints.