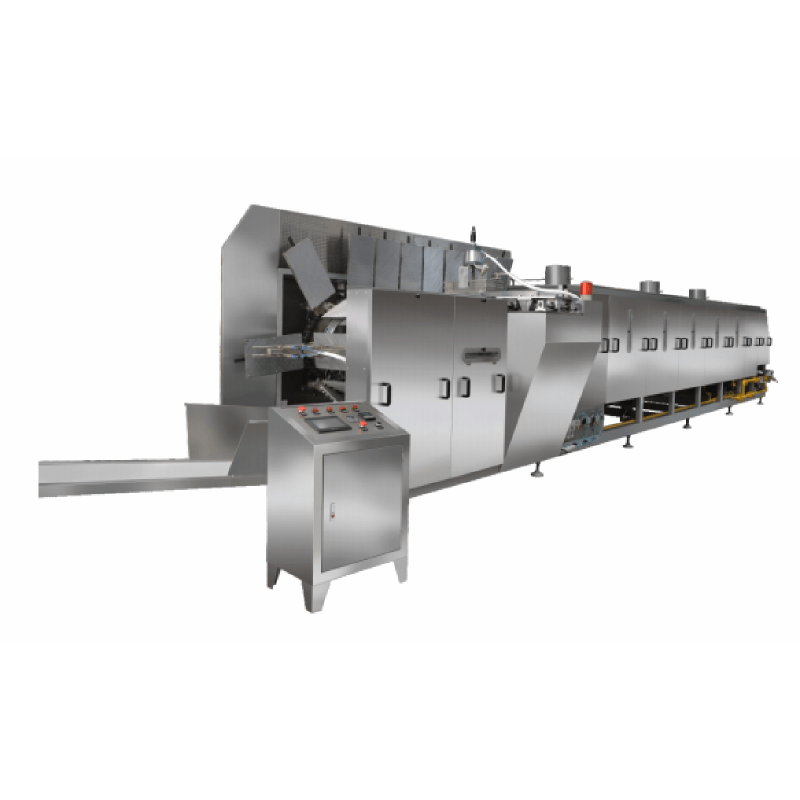

gas deck oven bakery

A gas deck oven bakery represents a cornerstone of modern commercial baking operations, combining traditional baking methods with advanced technology. These ovens feature multiple deck configurations, each independently controlled for temperature and timing, allowing bakers to simultaneously prepare various products with precision. The heating system utilizes natural gas or propane to generate consistent, even heat distribution through specially designed burners and heat exchangers. Each deck is constructed with heavy-duty materials, typically including stone or steel plates that retain and radiate heat effectively. The oven's design incorporates steam injection systems, crucial for achieving the perfect crust on bread products. Digital control panels enable precise temperature management and timing settings, while the modular construction allows for customization based on production needs. The gas deck oven's efficient heat circulation system ensures uniform baking results across all deck levels, making it ideal for producing artisanal bread, pastries, pizzas, and other baked goods. Modern safety features include automatic gas shut-off systems, temperature limiters, and insulated doors to prevent heat loss and ensure operator safety.