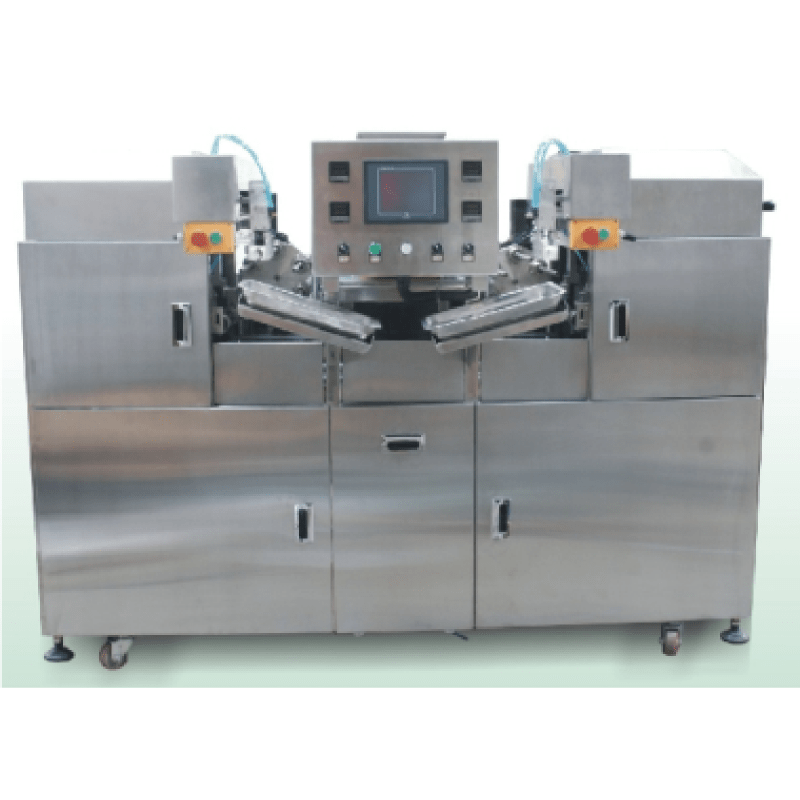

industrial bread dough mixer

The industrial bread dough mixer stands as an essential piece of equipment in modern bakery operations, combining power, precision, and versatility to meet high-volume production demands. This robust machine features a heavy-duty motor system capable of handling large batches of dough, typically ranging from 50 to 500 pounds per cycle. At its core, the mixer employs a sophisticated dual-arm mixing mechanism that replicates traditional kneading techniques while ensuring consistent results across batches. The machine's bowl is constructed from food-grade stainless steel, offering durability and easy cleaning, while its variable speed settings allow bakers to adjust mixing intensity based on different dough requirements. Advanced models incorporate digital controls for precise timing and speed management, along with programmable memory functions for storing specific recipes. Safety features include emergency stop buttons, bowl guards, and automatic shut-off systems. The mixer's versatility extends beyond bread dough, as it can handle various types of dough, including those for pastries, pizzas, and other baked goods. Integration capabilities with other bakery equipment make it a central component in automated production lines, while its energy-efficient design helps reduce operational costs.