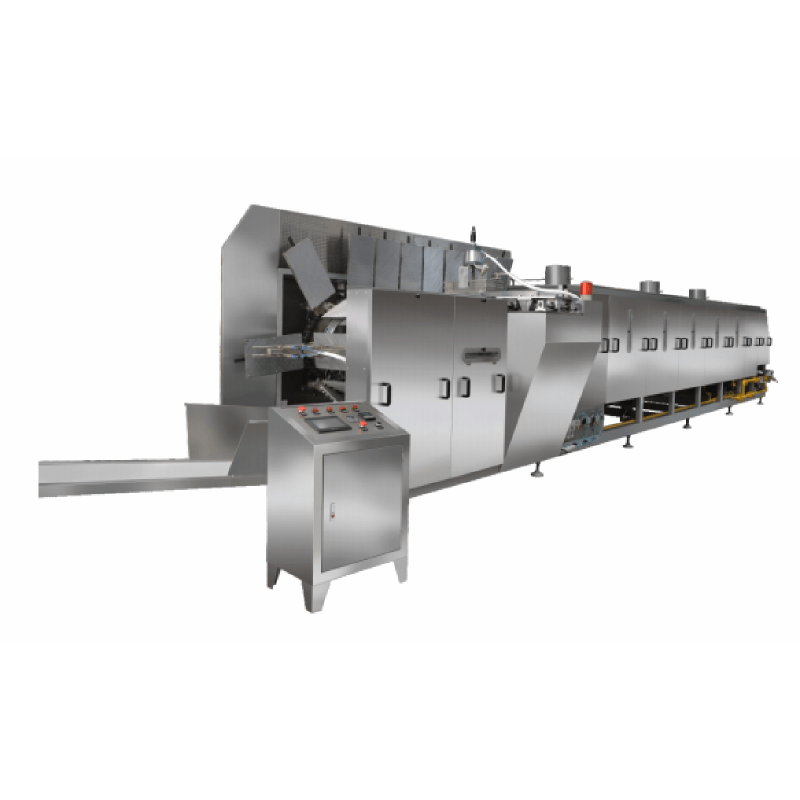

forno de convecção para padaria

Um forno de convecção para padaria é um equipamento avançado de uso comercial que revoluciona o processo de assar por meio de seu sofisticado sistema de circulação de ar. Ao contrário dos fornos tradicionais, essas unidades especializadas utilizam ventiladores potentes para distribuir o ar quente uniformemente por toda a câmara de cozimento, garantindo resultados consistentes e homogêneos no processo de assagem. A tecnologia incorpora controles de temperatura precisos, múltiplas posições de prateleiras e sistemas avançados de gerenciamento de umidade, permitindo que os padeiros alcancem resultados ótimos em uma variedade de produtos. Esses fornos geralmente apresentam painéis de controle digitais que permitem ajustes precisos de temperatura, funções de cronometragem e armazenamento programável de receitas. A câmara interna é projetada com construção em aço inoxidável para durabilidade e fácil limpeza, enquanto as portas de vidro duplo proporcionam excelente retenção de calor e eficiência energética. Fornos de convecção modernos para padarias muitas vezes incluem sistemas de injeção de vapor, essenciais para criar a crosta perfeita em pães e doces. Eles estão disponíveis em vários tamanhos para acomodar diferentes volumes de produção, desde modelos compactos de bancada até grandes unidades de chão capazes de manipular várias bandejas de tamanho completo simultaneamente. A versatilidade desses fornos vai além do simples assar, pois eles se destacam no assador, dourar e até desidratar, tornando-os ferramentas indispensáveis em padarias profissionais, restaurantes e operações de serviços alimentícios.