- Trang chủ

- Về Chúng Tôi

-

Sản Phẩm

- Thiết Bị Nướng Bánh

-

Chuẩn Bị Thực Phẩm

- Máy Trộn Thực Phẩm

- Máy Xay Ngâm

- Máy Trộn xoắn

- Máy Làm Lạnh Nước

- Máy cán bột

- Máy Chia Bột

- Máy Ép Bột

- Máy Ép Pizza

- Máy Thành Hình Bột

- Máy Cắt Bánh Mì

- Máy Làm Bánh

- Máy Xay Thịt

- Máy Cắt Thịt

- Cưa Xương

- Máy Làm Bánh Quả Thịt

- Máy Đổ Nhân Xúc Xích

- Máy chiết rót

- Máy Cắt Dưa Hấu Và Trái Cây

- Máy Cắt Thực Phẩm

- Máy Rửa Và Lột Sơ Ri

- Máy Làm Sữa Đậu Nành Và Đậu Phụ

- Máy Xay Lương Thực Điện

- Máy Ép Mía

- Máy Đun Nước

- Máy Đóng Chất Lỏng Vào Ly

- Máy Khử Trùng

- Máy Đóng Gói Hút Chân Không

-

Thiết Bị Nhà Bếp

- Nhóm Thiết Bị Nấu Ăn Loại Đặt Trên Sàn

- Nhóm Thiết Bị Nấu Ăn Loại Đặt Trên Bàn

- Chảo Rán

- Bàn Nướng Phẳng

- Bếp Gas

- Máy Làm Kebab

- Barbecue

- Máy Quay Thịt

- Bình Giữ Nhiệt Thực Phẩm

- Giỏ Hấp Gạo

- Bain-Marie

- Màn Hình Giữ Nhiệt

- Máy Nướng Xúc Xích

- Máy Làm Đơn Bánh Mì

- Tủ Hấp

- Bếp Từ

- Teppanyaki

- Thiết Bị Ướp Thịt

- Khay Chiên Khoai Tây

- Máy Làm Bánh Mì Kẹp

- Máy làm kẹo bông

- Máy làm bỏng ngô

- Lò Nướng Viên Cá

- Máy Làm Waffle

- Chảo Rán Bánh Donut

- Máy Làm Crepe

- Khay Giữ Nhiệt Và Đèn

- Máy Làm Donut

- Nồi Cơm Điện

- Máy Tan Sô Cô La

- Nồi Canh Điện

- Thiết bị làm lạnh

- Thiết Bị Quầy Bar

- Thép Không Gỉ

-

Dây Chuyền Sản Xuất

- Tuyến Xử Lý Cam

- Máy Cuộn Trứng Thủ Công GL-12

- Máy Cuộn Trứng Thủ Công GL-06

- Máy Định Hình Cuộn Rong Biển

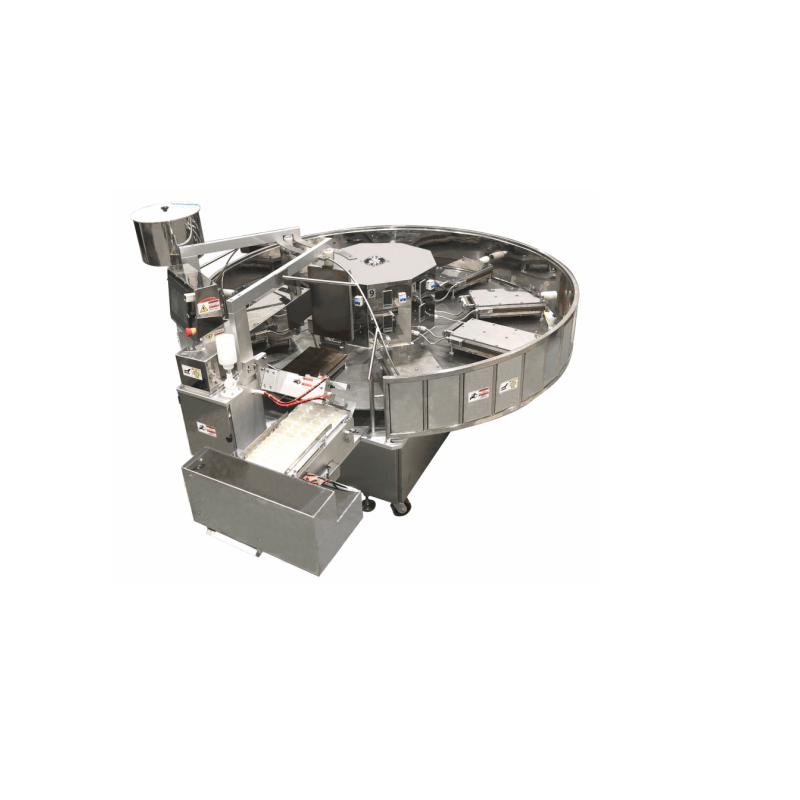

- Máy Tự Động Làm Cuộn Phượng Hoàng

- Máy Cuộn Trứng Tự Động

- Máy Chiên Trứng Tự Động Guijiabei

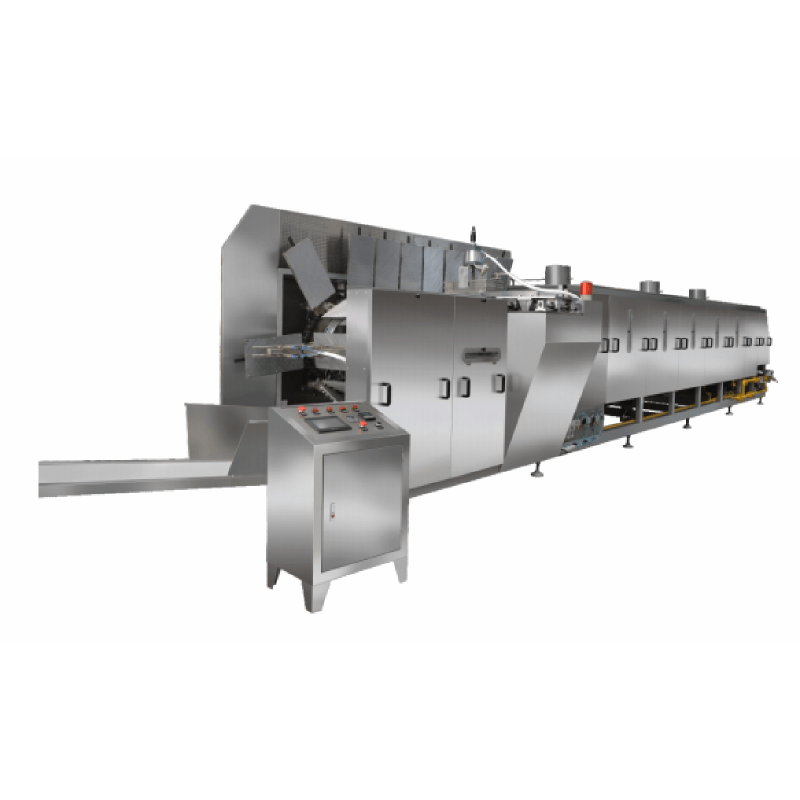

- Dây Chuyền Sản Xuất Cuộn Trứng Wafer Gas Tự Động

- Dây Chuyền Sản Xuất Waffle Mềm Tám Chế Độ

- Dây Chuyền Sản Xuất Bánh Kếp Tự Động Phong Cách Châu Âu

- Dây Chuyền Sản Xuất ShaQima

- Tuyến Sản Xuất Bánh Mì Hơi Mini Tự Động

- Tuyến Sản Xuất Bánh Trứng (9 Mô Đun) Tự Động

- Quầy Pha Chế Bar Tùy Chỉnh Series

- Bếp Tiệc Buffet Khách Sạn Thiết Kế Tùy Chỉnh Series

- Giặt Ủi

- Dụng Cụ

- Máy Rửa Bát

- dịch Vụ

- Tin tức

- Liên Hệ Với Chúng Tôi