best convection oven for bakery

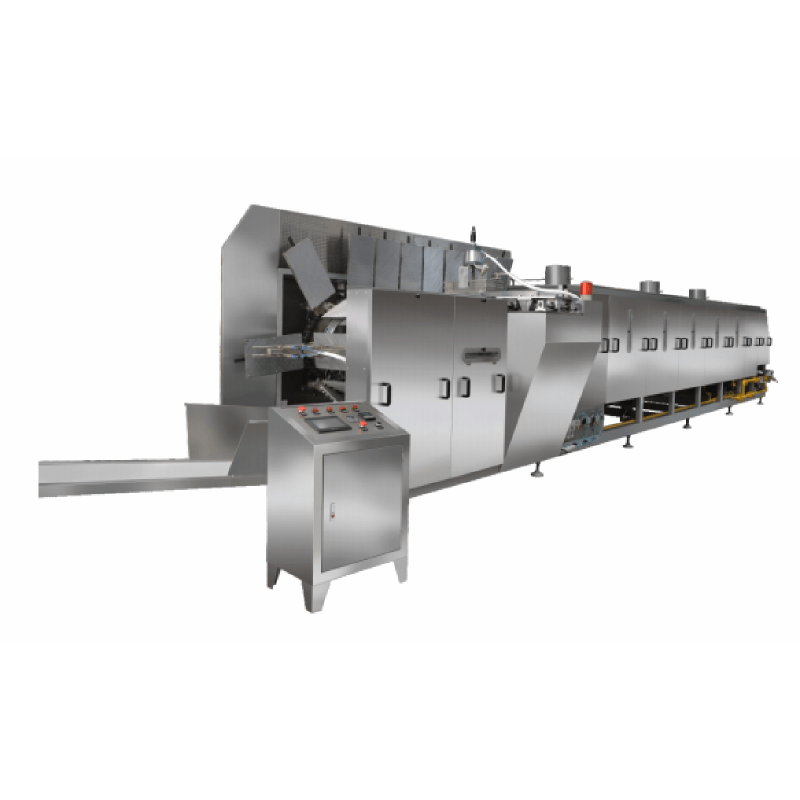

The commercial convection oven stands as the cornerstone of modern bakery operations, offering unparalleled performance and versatility for professional baking needs. This advanced baking solution features powerful fans that circulate hot air uniformly throughout the cavity, ensuring consistent and even baking results every time. With precise temperature control ranging from 50°F to 500°F, digital programming capabilities, and multiple rack positions, these ovens can handle everything from delicate pastries to artisan bread. The best models incorporate steam injection systems, which are crucial for achieving the perfect crust development and optimal rise in bread products. Advanced features include programmable recipe storage, automated humidity control, and energy-efficient operations that reduce power consumption while maintaining superior baking performance. The double-pane glass doors provide excellent insulation while allowing bakers to monitor their products without opening the oven. These ovens typically accommodate full-size sheet pans and feature stainless steel construction for durability and easy cleaning. Built-in safety features such as cool-touch exteriors and automatic shutdown systems ensure safe operation in busy bakery environments.