giá lò nướng đối lưu cho tiệm bánh

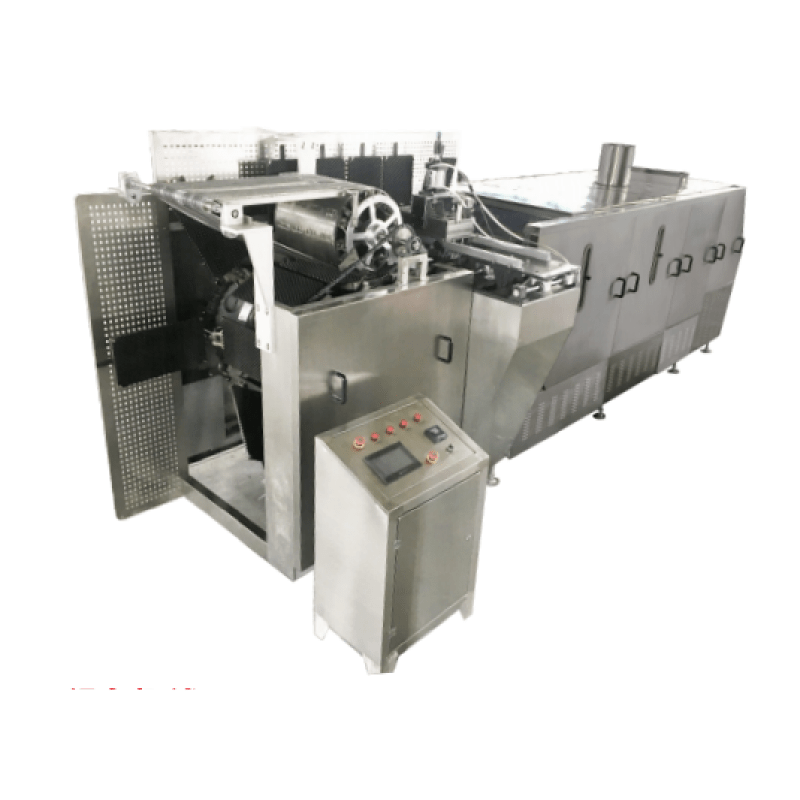

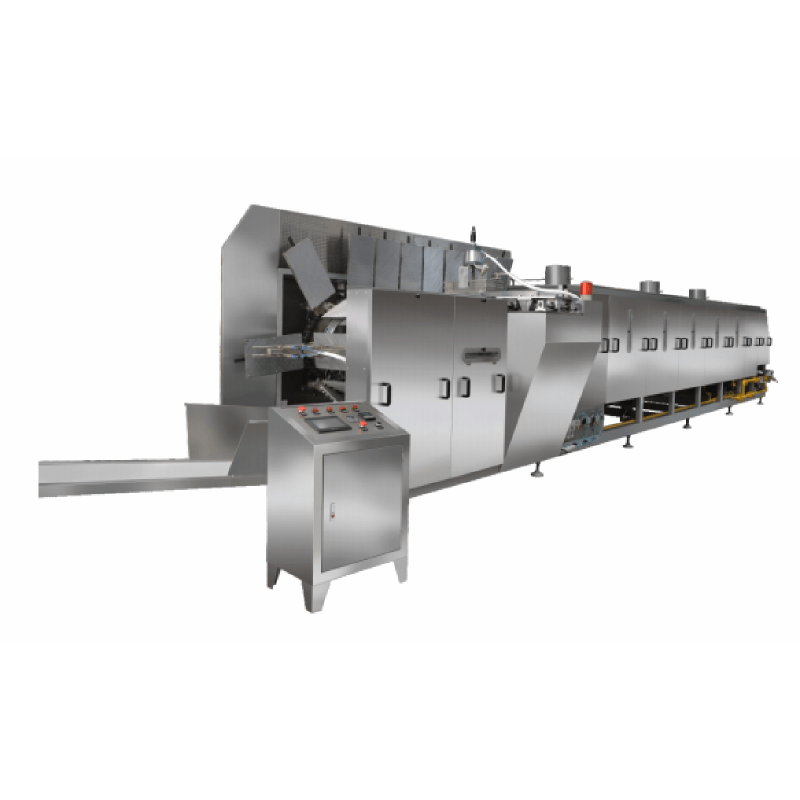

Lò đối lưu cho tiệm bánh đại diện cho một khoản đầu tư đáng kể vào thiết bị nướng chuyên nghiệp, với giá cả phản ánh các tính năng và khả năng tiên tiến của chúng. Những lò nướng chuyên dụng này sử dụng quạt mạnh mẽ để tuần hoàn không khí nóng đều khắp buồng nướng, đảm bảo kết quả nhất quán trên nhiều khay nướng. Phạm vi giá thường dao động từ 2.000 đô la cho các mẫu cơ bản đến 15.000 đô la hoặc hơn cho các đơn vị cấp thương mại, tùy thuộc vào kích thước, công suất và các tính năng kỹ thuật. Các lò đối lưu hiện đại tích hợp điều khiển kỹ thuật số, nhiều chế độ nấu ăn và hệ thống kiểm soát nhiệt độ chính xác. Chúng cung cấp các cài đặt có thể lập trình cho các công thức khác nhau, khả năng tiêm hơi nước và hoạt động tiết kiệm năng lượng giúp giảm chi phí vận hành lâu dài. Việc xem xét đầu tư phải tính đến các yếu tố như khối lượng sản xuất, không gian sẵn có và yêu cầu nướng cụ thể. Những chiếc lò này được thiết kế để đáp ứng nhiều nhu cầu nướng khác nhau, từ bánh mì và bánh ngọt đến bánh quy và bánh ngọt, làm cho chúng trở thành những bổ sung đa năng cho bất kỳ hoạt động kinh doanh bánh nào. Giá cả cũng phản ánh các tính năng bổ sung như cửa kính ba lớp để giữ nhiệt tốt hơn, cấu trúc nặng duty để bền bỉ và các tính năng an toàn tiên tiến bảo vệ cả người vận hành lẫn sản phẩm.