blast freezer for bakery

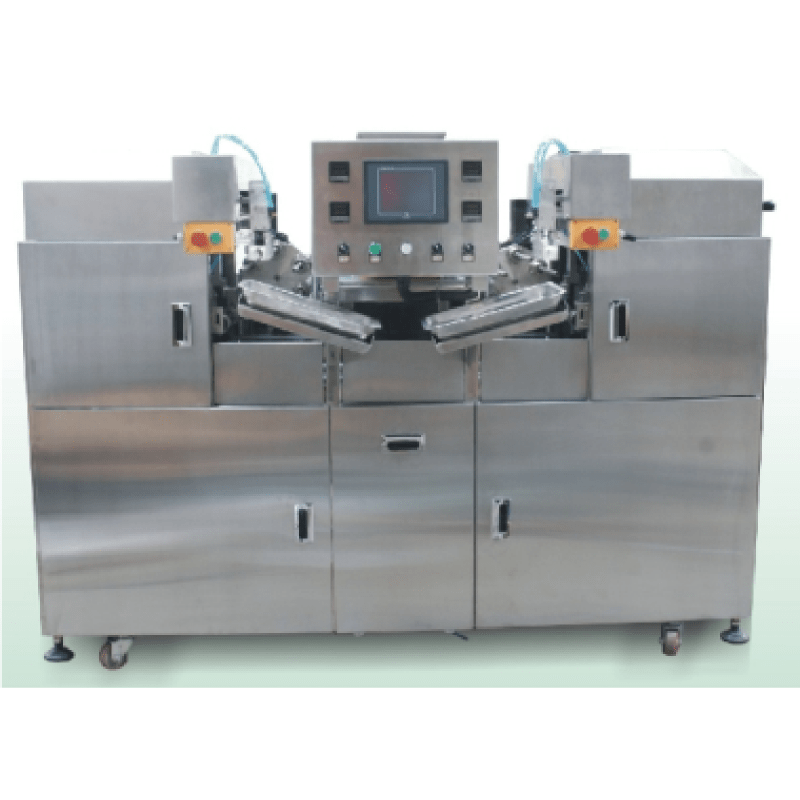

A blast freezer for bakery is an essential piece of equipment designed to rapidly freeze baked goods while maintaining their quality, texture, and taste. This specialized freezing system operates by circulating extremely cold air at high velocities around the products, quickly reducing their temperature to below freezing point. The rapid freezing process prevents the formation of large ice crystals, which can damage the cellular structure of baked goods. These freezers are equipped with powerful compressors and advanced temperature control systems that can achieve temperatures as low as -40°F (-40°C). They feature adjustable shelving systems to accommodate various product sizes and quantities, and many models include touchscreen interfaces for precise temperature and time control. The technology employs blast chilling cycles that can be customized based on product type, size, and quantity, ensuring optimal results for different bakery items. These units are particularly valuable for commercial bakeries, as they can handle large volumes of products while maintaining consistent quality. The blast freezer's ability to quickly freeze items helps preserve the freshness, flavor, and structural integrity of breads, pastries, cakes, and other baked goods, making it an indispensable tool for modern bakery operations.