blast freezer commercial

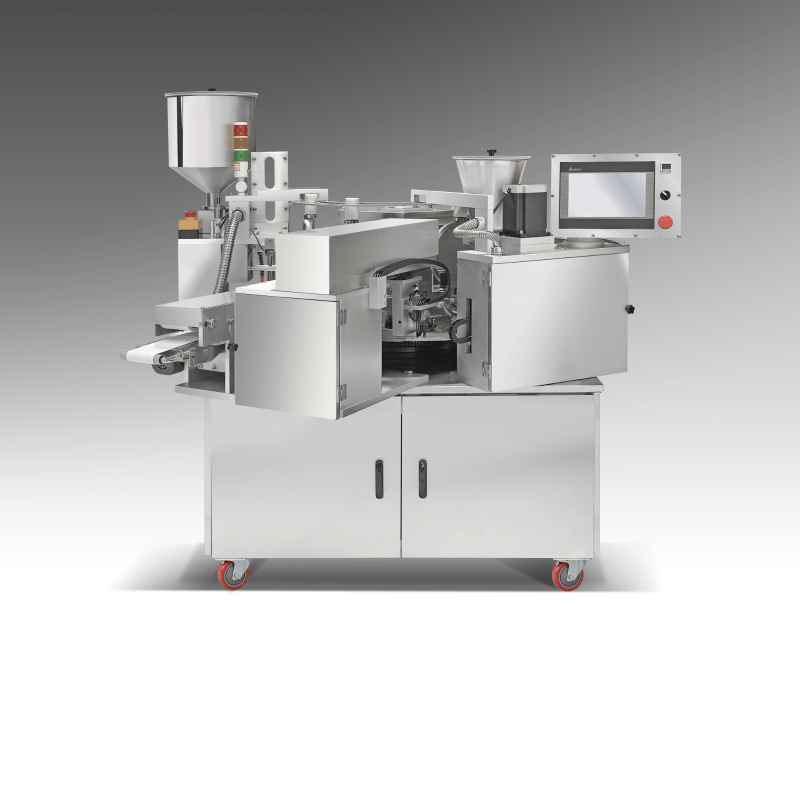

A blast freezer commercial is an advanced cooling system designed to rapidly reduce the temperature of food products, preserving their quality and extending shelf life. This sophisticated equipment utilizes powerful refrigeration technology and high-velocity airflow to achieve temperatures as low as -40°F (-40°C) in a matter of hours. The system works by circulating extremely cold air at high speeds around the product, creating a process known as quick-freezing. This rapid freezing prevents the formation of large ice crystals within food cells, maintaining the product's texture, flavor, and nutritional value. The commercial blast freezer features adjustable temperature controls, multiple shelf configurations, and robust stainless steel construction designed for heavy-duty use. It includes advanced digital control panels for precise temperature management and monitoring, ensuring consistent freezing results. These units are equipped with efficient compressors and evaporators that provide optimal cooling performance while maintaining energy efficiency. The blast freezer's versatile design accommodates various food products, from prepared meals to raw ingredients, making it essential equipment for restaurants, catering services, and food processing facilities.