table top blast freezer

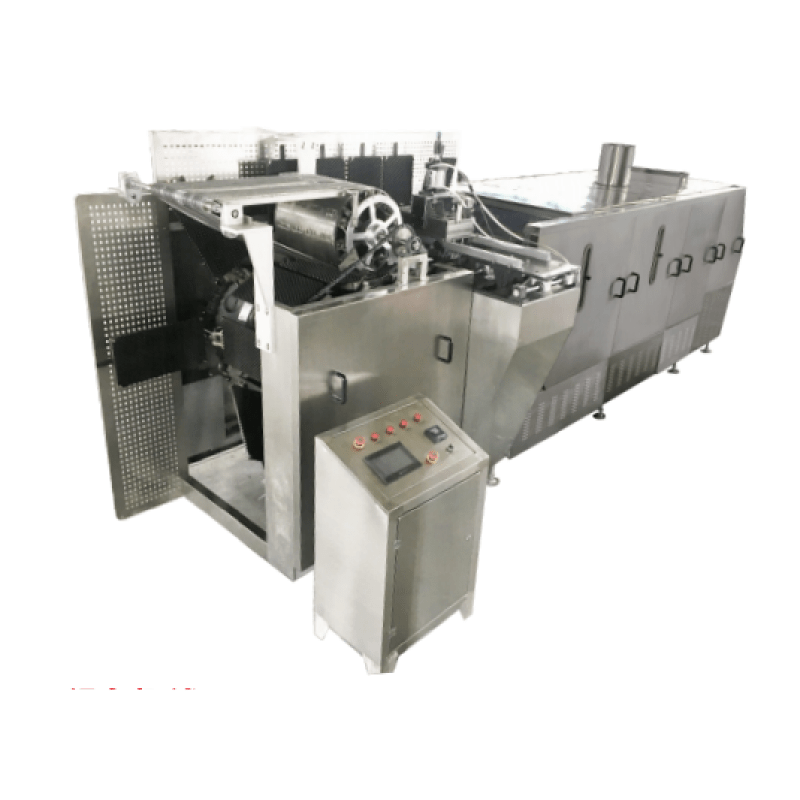

The table top blast freezer represents a revolutionary advancement in rapid cooling technology, designed specifically for commercial and laboratory applications where precise temperature control and quick freezing are essential. This compact yet powerful unit efficiently freezes products from room temperature to deep freeze conditions in a fraction of the time compared to conventional freezers. Operating with advanced compression technology, it achieves temperatures as low as -40°C (-40°F), making it ideal for preserving food quality, maintaining sample integrity, and meeting strict food safety standards. The unit features a user-friendly digital control panel that allows precise temperature adjustment and monitoring, while its stainless steel construction ensures durability and easy cleaning. With its space-saving design, the table top blast freezer fits seamlessly into various environments, from professional kitchens to research laboratories. The system incorporates smart airflow technology that ensures uniform freezing throughout the chamber, preventing ice crystal formation that can damage sensitive materials. Additionally, it includes adjustable shelving systems, allowing for flexible organization of different sized items, and a well-insulated cabinet that maintains energy efficiency while providing optimal freezing performance.