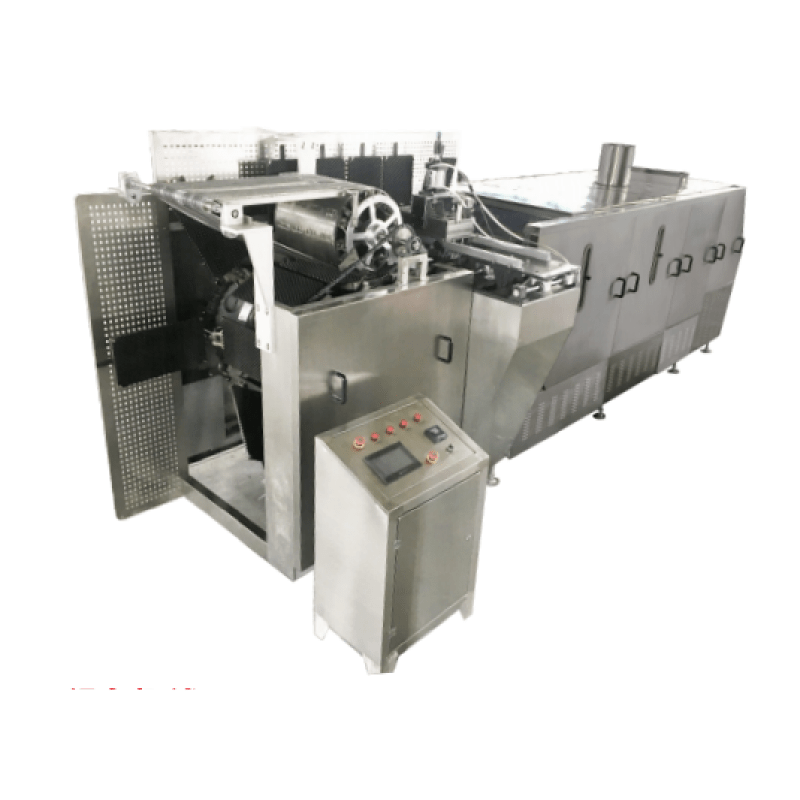

industrial blast freezer for sale

The industrial blast freezer represents a cutting-edge solution for rapid freezing requirements in commercial and industrial settings. This advanced freezing system employs powerful cooling technology to quickly reduce product temperatures to below freezing point, typically reaching -40°F (-40°C) or lower. The unit features a robust stainless steel construction, ensuring durability and compliance with food safety standards. Its versatile design accommodates various product sizes and types, from fresh produce to prepared meals and meat products. The blast freezer utilizes high-velocity airflow technology, circulating cold air at speeds up to 3 meters per second, which significantly reduces freezing time and prevents the formation of large ice crystals. This preservation method maintains product quality by minimizing cellular damage during the freezing process. The system includes adjustable shelving configurations, allowing for maximum space utilization and efficient batch processing. Advanced digital controls enable precise temperature management and monitoring, while the energy-efficient compressor system optimizes power consumption during operation. The unit also features automated defrost cycles and easy-clean surfaces, reducing maintenance requirements and downtime.