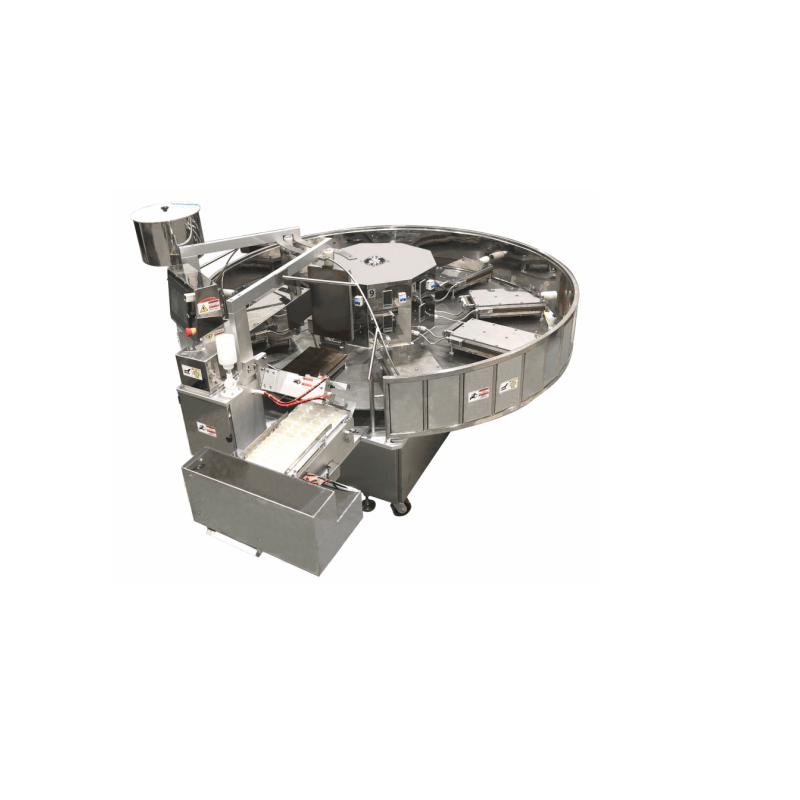

continuous air blast freezer

A continuous air blast freezer represents a cutting-edge solution in industrial food processing, designed to rapidly freeze products through high-velocity cold air circulation. This sophisticated system operates on a continuous basis, allowing products to move through the freezing chamber on conveyors while exposed to precisely controlled air temperatures, typically ranging from -30°F to -40°F. The technology employs powerful fans that direct cold air across the product surface, creating rapid heat transfer and ensuring consistent freezing throughout the item. The system's design incorporates multiple zones, including pre-cooling, deep freezing, and equilibration sections, each optimized for specific stages of the freezing process. Modern continuous air blast freezers feature advanced controls for temperature regulation, airflow management, and belt speed adjustment, enabling processors to customize parameters based on product requirements. These systems excel in handling various food items, from meat and poultry to prepared meals and baked goods, making them versatile assets in food processing facilities. The freezer's efficient design minimizes frost formation and reduces energy consumption while maintaining product quality through rapid freezing that prevents large ice crystal formation.