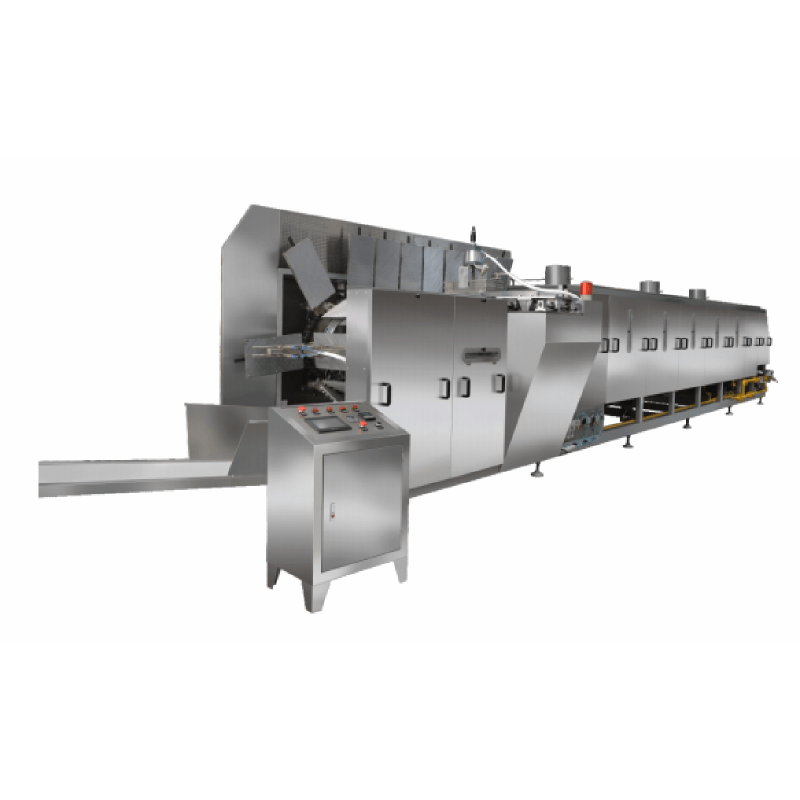

revolving deck oven

A revolving deck oven represents a pinnacle of modern baking technology, combining efficient heat distribution with precise temperature control. This innovative baking solution features multiple rotating decks that ensure consistent and uniform baking results across all products. The system operates through a sophisticated mechanism where decks rotate horizontally while maintaining steady temperature zones, allowing for simultaneous baking of different products. Each deck is independently controlled, offering bakers the flexibility to adjust temperature, timing, and rotation speed according to specific recipe requirements. The oven's design incorporates advanced heat circulation technology, utilizing both radiant and convection heating methods to achieve optimal baking conditions. With its substantial capacity and space-efficient footprint, the revolving deck oven can handle large production volumes while maximizing floor space usage. The construction typically features high-grade stainless steel and premium insulation materials, ensuring durability and energy efficiency. Modern models come equipped with digital controls, programmable settings, and smart monitoring systems that enable precise operation and consistent results. These ovens are particularly valuable in commercial bakeries, hotels, restaurants, and industrial baking facilities where high-volume production and consistent quality are essential.