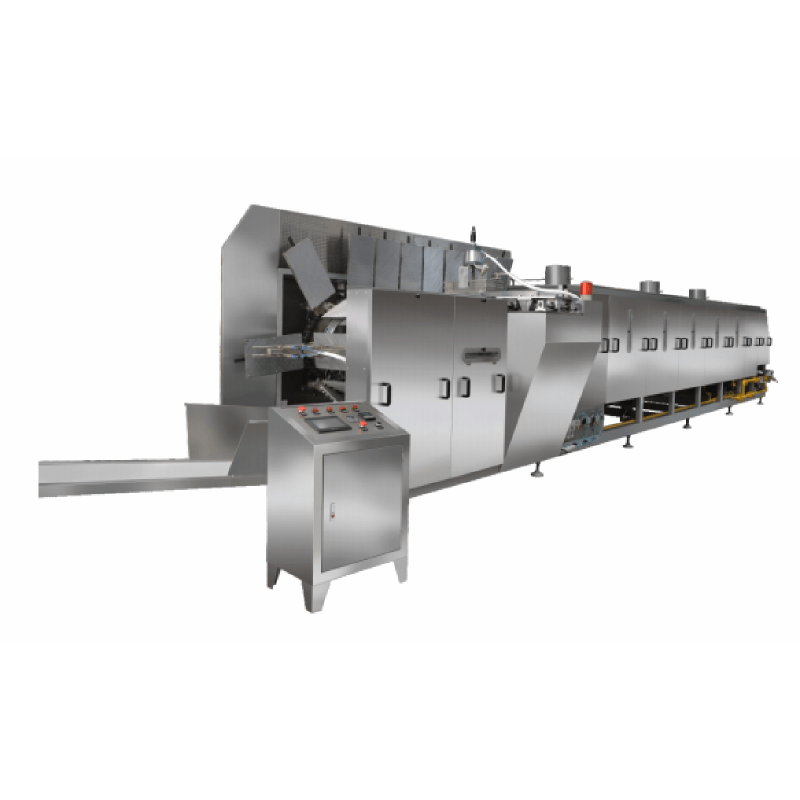

bakery deck oven for sale

The bakery deck oven represents a pinnacle of professional baking equipment, combining traditional baking methods with modern technology. This versatile piece of equipment features multiple independent decks, each offering precise temperature control and even heat distribution for consistent baking results. The oven's robust construction includes high-grade stainless steel exterior, ensuring durability and easy maintenance, while the interior features specialized baking stones that retain and distribute heat effectively. Each deck operates independently with separate top and bottom heating elements, allowing bakers to simultaneously prepare different products at varying temperatures. The steam injection system provides optimal humidity control, essential for achieving the perfect crust on bread and pastries. Advanced digital controls enable precise temperature management and timing functions, while the large viewing windows and internal lighting allow constant monitoring of the baking process. The oven's energy-efficient design incorporates superior insulation materials, reducing heat loss and operating costs. With dimensions suitable for commercial operations, this deck oven can accommodate multiple full-size baking sheets per deck, making it ideal for high-volume production while maintaining artisanal quality.