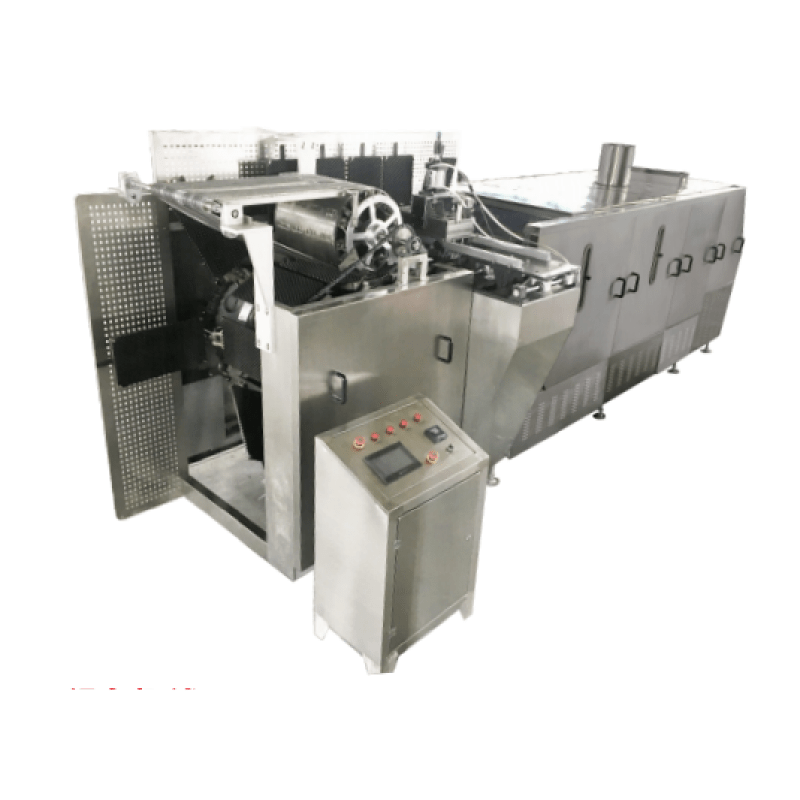

blast freezer for gelato

A blast freezer for gelato is an essential piece of equipment in modern gelato production, designed to rapidly freeze freshly made gelato while preserving its smooth texture and rich flavors. This specialized freezing system operates by circulating extremely cold air at high velocities, typically reaching temperatures between -30°C and -40°C. The rapid freezing process prevents the formation of large ice crystals, ensuring the gelato maintains its creamy consistency and authentic taste. The blast freezer features advanced temperature control systems, allowing precise management of the freezing cycle. It comes equipped with multiple shelves or positions to accommodate various batch sizes and production needs. The unit's intelligent programming capabilities enable operators to set specific freezing times and temperatures for different gelato recipes, ensuring consistent results every time. Most modern blast freezers include features such as automatic defrosting systems, energy-efficient operations, and digital displays for easy monitoring. The equipment's design typically incorporates food-grade stainless steel construction, ensuring durability and maintaining strict hygiene standards. Additionally, many models offer the flexibility to adjust fan speeds and freezing intensities, making them suitable for various gelato formulations and production volumes.